Inrush Current

ZJ-YL300A

The impulse current tester produced by our company is made in accordance with the requirements of the standard IEC61851-1: 2017-02, version 3.0 Electric vehicle conductive charging system Part 1: General requirements Chapter 12.2.6.

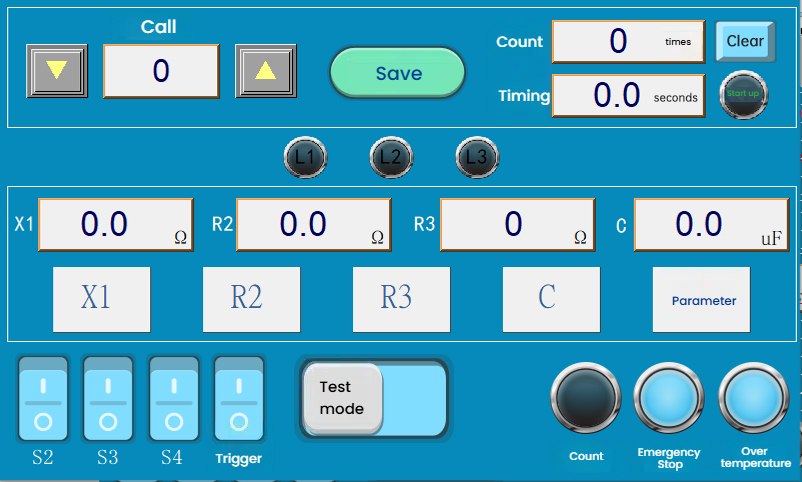

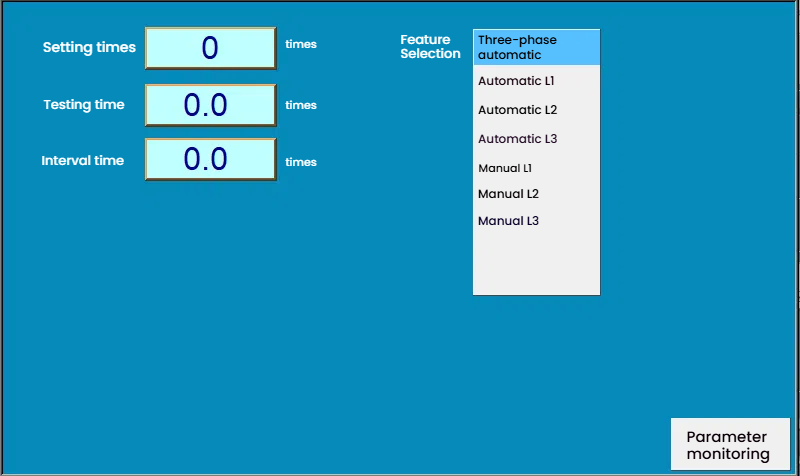

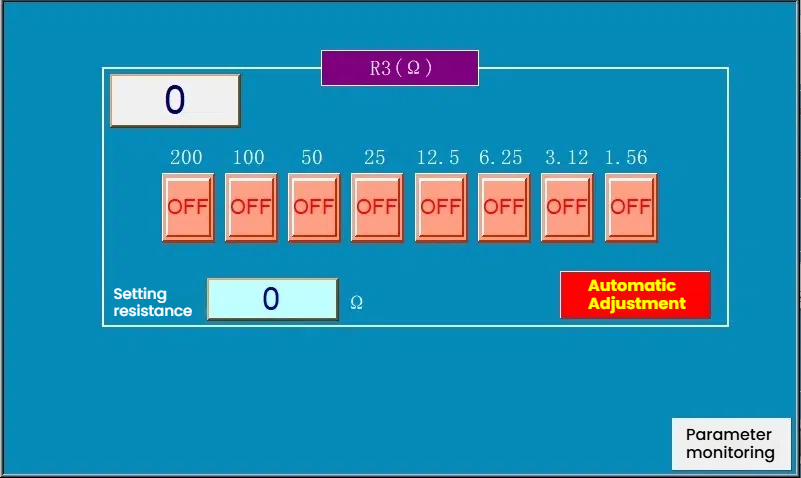

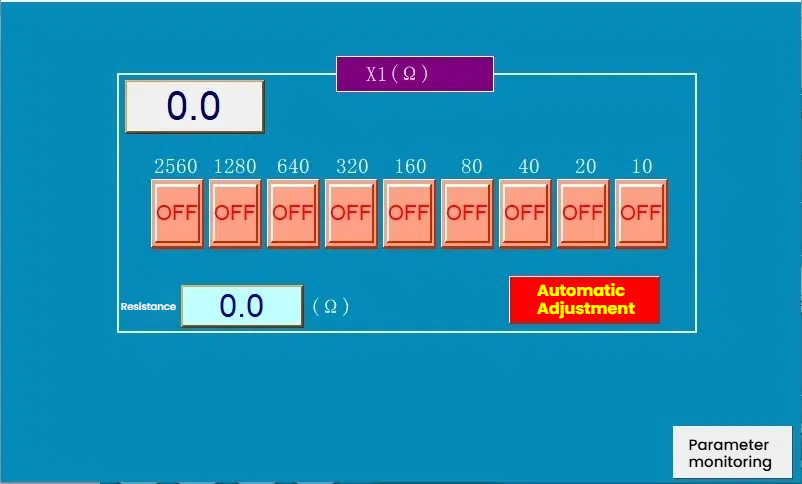

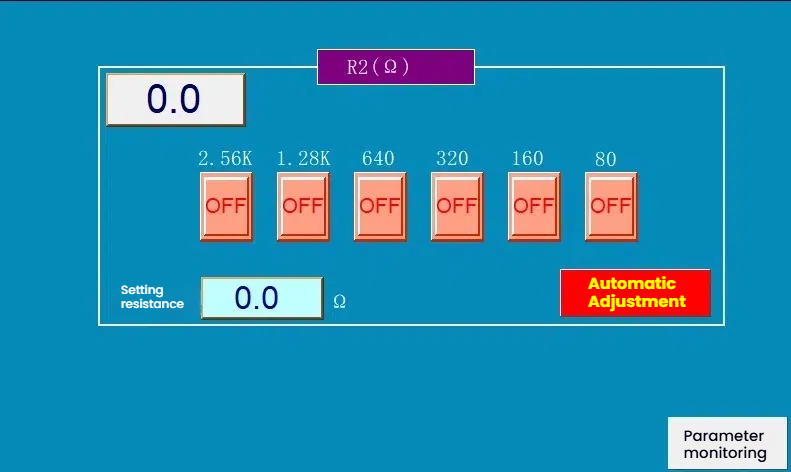

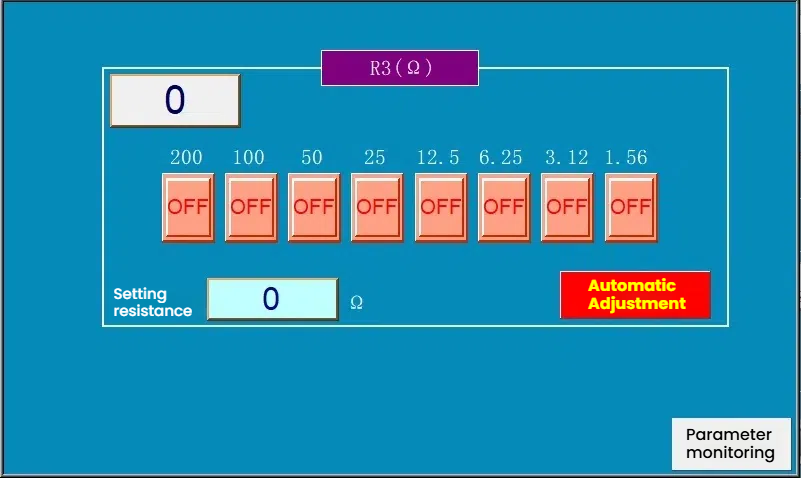

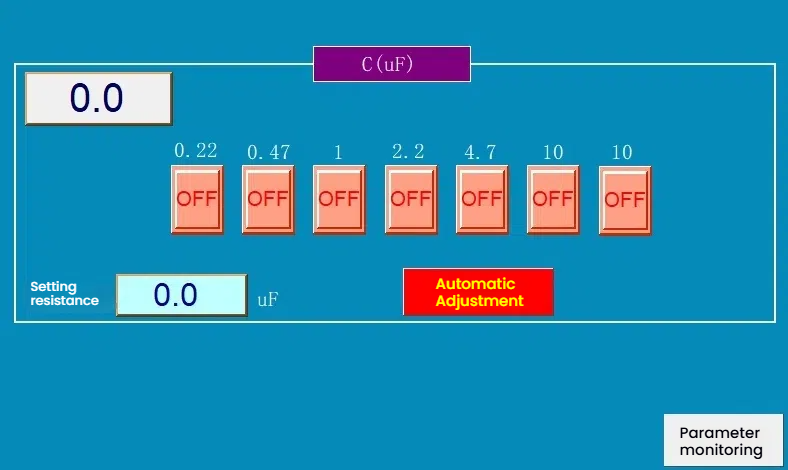

The equipment is controlled by PLC+touch screen.

Meet the following standards:

According to ISO 17409: 2015 Section 8.2.2, AC electric vehicle supply equipment should be able to withstand surge current.

The following values are specified in ISO 17409:

• After closing the contactor in the electric vehicle supply equipment at the peak value of the supply voltage, the electric vehicle supply equipment should be able to withstand a peak of 230 A for a duration of 100µs.

• In the next second, the electric vehicle supply equipment should be able to withstand 30 A (RMS).

According to /EC TS 61439-7, compliance with this requirement can be verified by testing the entire electric vehicle supply equipment or a single switch device.

The protection device should be selected so that it will not trip due to the inrush current.