-

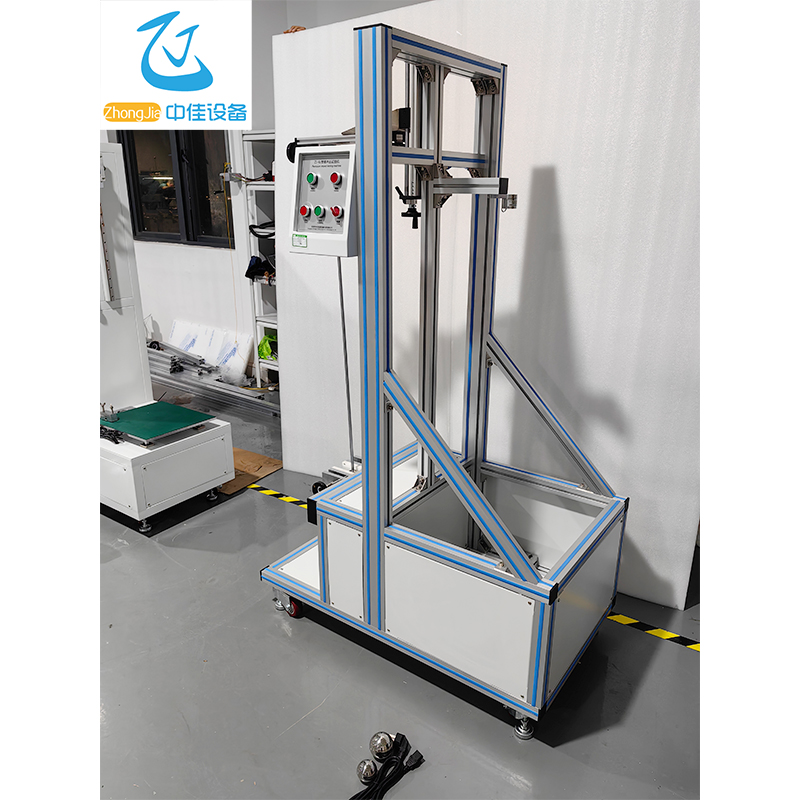

Pendulum Impact Testing Machine

ZJ-4J

Send Email Details

The equipment must meet the test requirements of clauses 6.2.10.2 and 7.11.2 of GB/T 20234.1-2023, and is applicable to mechanical strength tests and drop ball impact tests of vehicle plugs, sockets, vehicle connectors and vehicle jacks. The mounting bracket is adjustable up and down, left and right. The swing arm is adjustable front and back, left and right, and the angle is adjustable, with a foot cup at the bottom. -

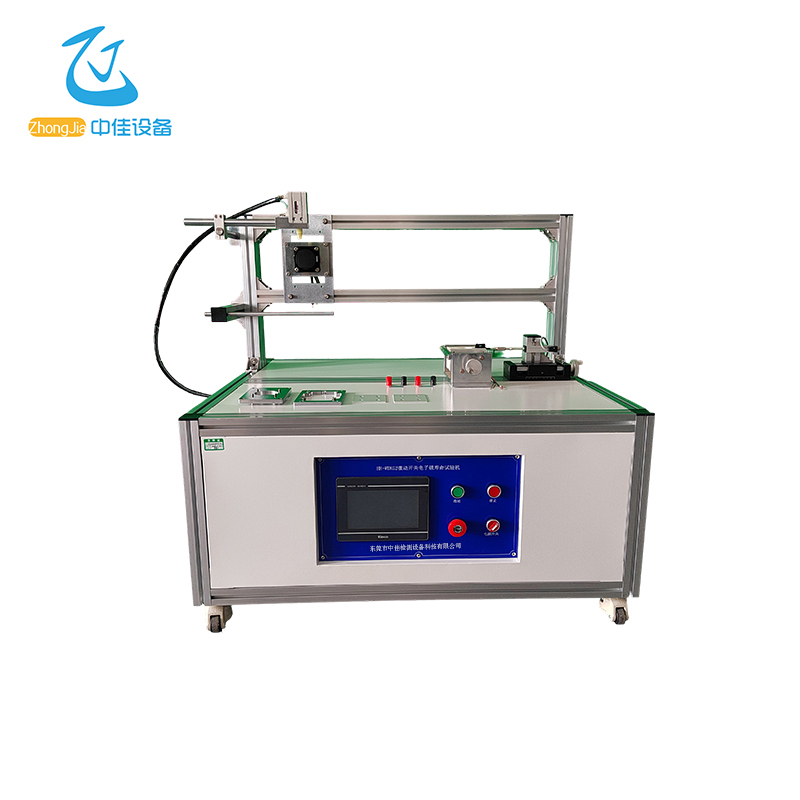

Charging Gun Electronic Locking Device Comprehensive Testing Machine

ZJ-AJ01

Send Email Details

The device meets the test requirements of GB/T18487.1-2023 Clause 10.6, GB/T 20234.1-2023 Clauses 6.3.4 and 7.15.2, and IEC EN 62196-1-2022 Chapter 14, and is suitable for life testing of the electronic lock of the charging gun, with a foot pad at the bottom.

The electronic lock can be powered on and off, and the mechanical life of the electronic lock push rod extension and retraction, as well as the signal feedback life, the push rod is tested with the specified tension and thrust mode, and the mechanical lock is tested with external pressure. -

Charging Gun Plug-In Life Testing Machine

ZJ-CBSM01

Send Email Details

This equipment is suitable for the charging gun plug and socket breaking capacity and normal operation life test, locking device test, and plug-in force test. It uses servo electric cylinders, servo motors, air cylinders, etc. as power, and a small fixture to clamp the sample. The touch screen and programmable controller (PLC) are the control center. It has superior performance, easy operation, and a high degree of automation. It can clamp the charging gun, automatically immerse the charging gun in acid rain solution, saline solution, and muddy water solution in turn, and then automatically take it out and insert it into the charging gun holder. The last power-on is 1.5 hours, and the action is repeated to simulate the plug-in life of the charging gun outdoors. All test items meet the requirements of GB/T18187.1-2015, GB/T20234.1-2023, and GB/T11918.1-2014. -

Cable Fixing Parts Tension And Torque Testing Machine

ZJ-LN02

Send Email Details

This equipment meets the test requirements of clause 7.7 of GB/T20234.1-2023, chapter 23 of GB/T11918.1-2014, and chapter 25 of IEC 62196-1:2022. It can withstand tension and torque tests on non-detachable power plugs and vehicle plugs.

It is used to perform tension and torque tests on power cords of appliances with power cords, appliances that are intended to be permanently connected to fixed wiring with flexible cords, household electrical appliances, medical devices, etc. at the wiring terminals to check whether the clamping device is firm. The instrument is easy to operate, has a reasonable structure, and beautiful appearance.

The cable is subjected to tension tests 100 times, with tension applied for 1S each time. Then, the cable is subjected to a torque test for 1min.

Check whether the displacement of the cable from the fixing meets the standard. -

Charging Interface Cable Bending Test Machine

ZJ-WQ01

Send Email Details

This equipment must meet the test requirements of Chapter 6.2.10.4 of GB/T20234.1-2023, Chapter 24.4 of GB/T11918.1-2014, and Chapter 26.4 of IEC 62196-1:2022, and is suitable for bending tests of non-detachable electrical accessories such as charging guns.

This equipment is controlled by PLC and touch screen, which is convenient to control. The angle, speed and number of times can be set. Fix the sample on the fixture, add a certain load, and shake the fixture left and right during the test. After a certain number of times, check its wire breakage rate, or check its total number of swings when it cannot be powered on. This machine can count automatically. When the sample is bent to the point where it cannot be powered on, the instrument automatically stops working. This equipment can also be tested with load, and a load wiring port is reserved.

- Home

-

Our Services

- Charging Gun Pile Testing Equipment

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Charging Gun Pile Testing Equipment

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Display

- News

- About

- Contact Us

- Partners