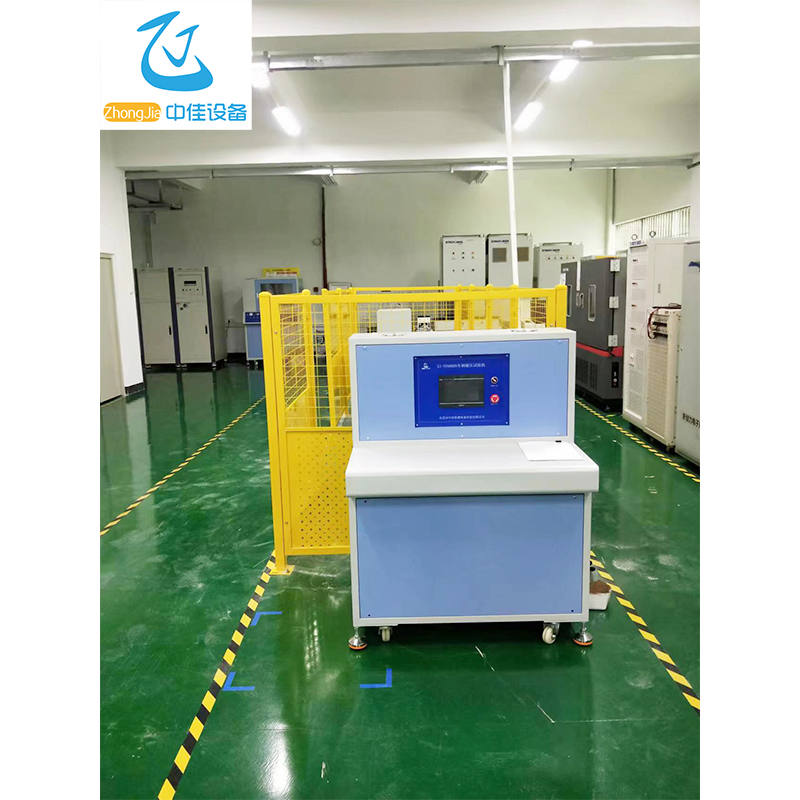

Vehicle Rolling Test Machine

ZJ-NY6000N

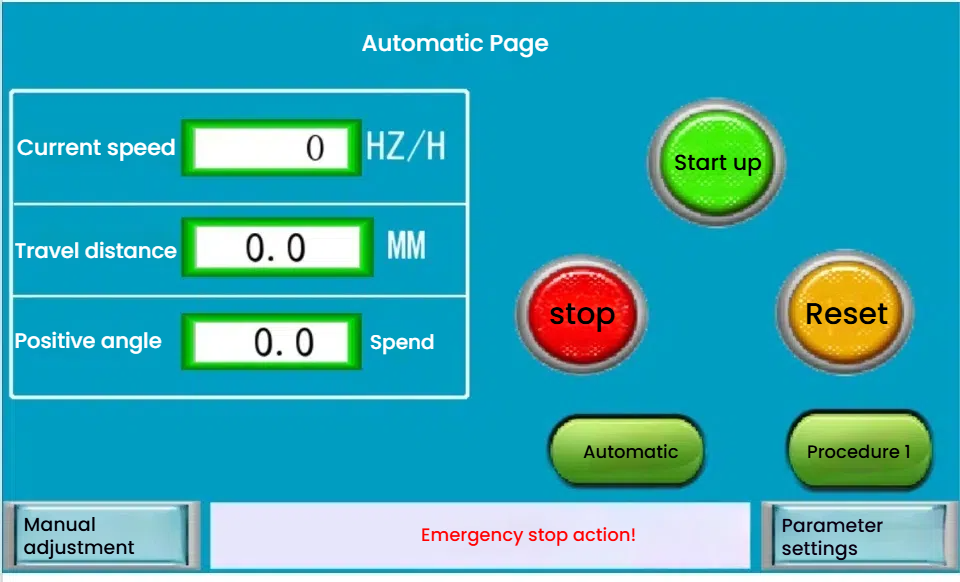

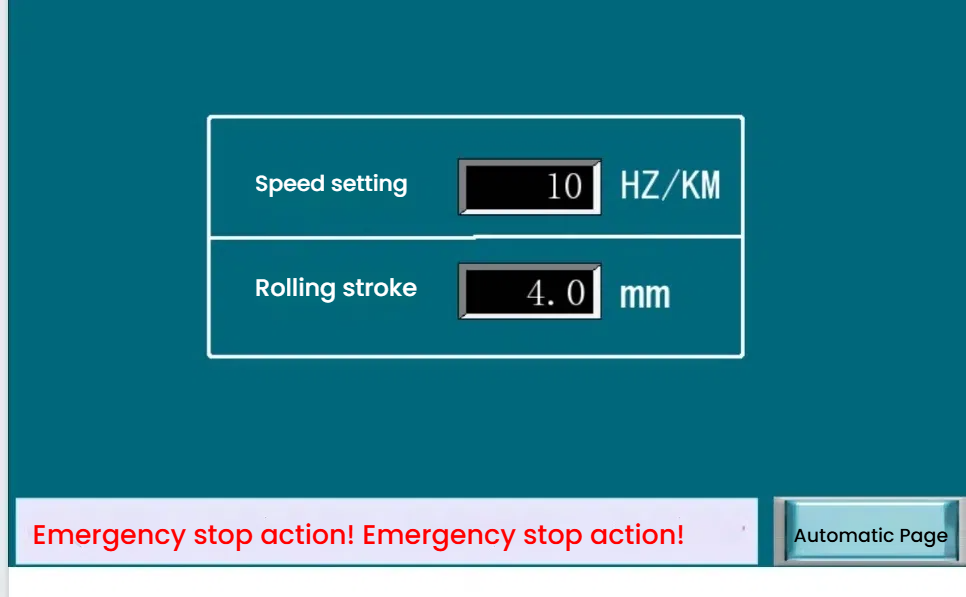

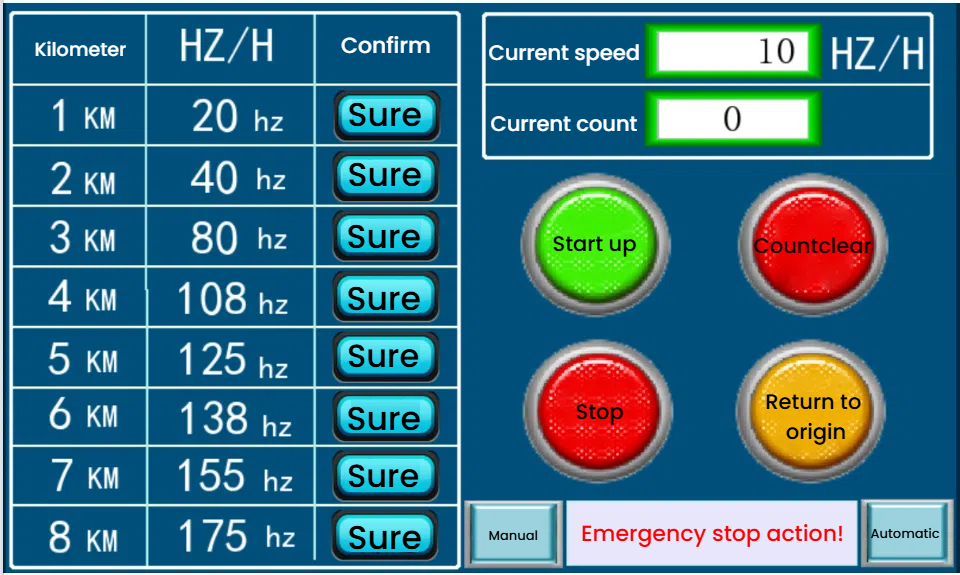

This test device is designed and manufactured according to UL2251 and GB/T 20234.1-2015. It is suitable for pressure life tests of various types of electric vehicle charging piles. The power plug and vehicle plug with the cable recommended by the manufacturer are placed randomly on the cement ground. A car tire with the same load as P225/75R15 is used to press over the power plug or vehicle plug at a pressure of (4893±500N)N and a speed of (8±2)km/h (tire inflation pressure 218±13kPa) to simulate the ability of the power plug or vehicle plug to withstand vehicle rolling.