1. Power input: AC 220V

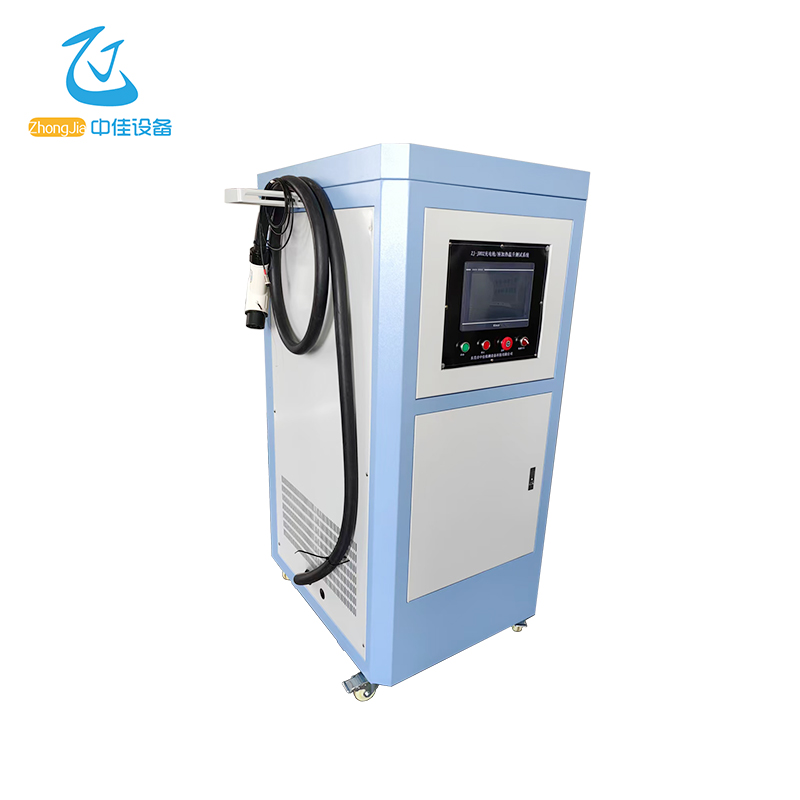

2. Control mode: PLC+touch screen+temperature controller

3. Heating mode: heating rod

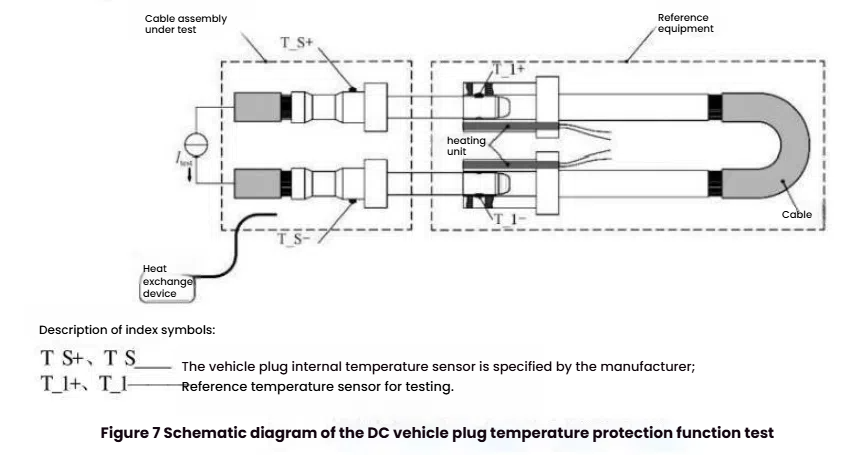

4. DC gun holder: charging gun holder D+, D- are heated separately,

2-way heating system, 2-way temperature measurement system, precise temperature control.

5. Heating range: room temperature ~ 150 degrees can be set

6. Heating rate: ≥2℃/min

7. Heating temperature acquisition range: -40~200℃

8. Heating temperature acquisition is PT100 thermocouple, 2-way independent acquisition

9. Heating temperature acquisition: resolution 0.1 degree, accuracy ≤±1 degree

10. Heating time: adjustable within the range of 0-999Min

11. Heating power can be adjusted automatically

12. When the heating temperature reaches the set value, there is a buzzer reminder function.

13. The heating gun holder is a national standard DC gun holder

14. Test station: 1 station DC

15. Data processing: temperature self-generated curve, with data storage and export functions, export Excel table data

16. With thermocouple line for collecting the tested product: PT1000, NTC signal, thermocouple data can be collected.

Collection channels 16 channels,

Collection range: -40~200℃

Collection accuracy: ≤0.1℃

17. Equipped with 150 square cables for connecting loads, 3 meters long

18. Equipment size: about 800*900*1700mm high

19. Equipment weight: about 150kg