Serial number | Technical Parameters |

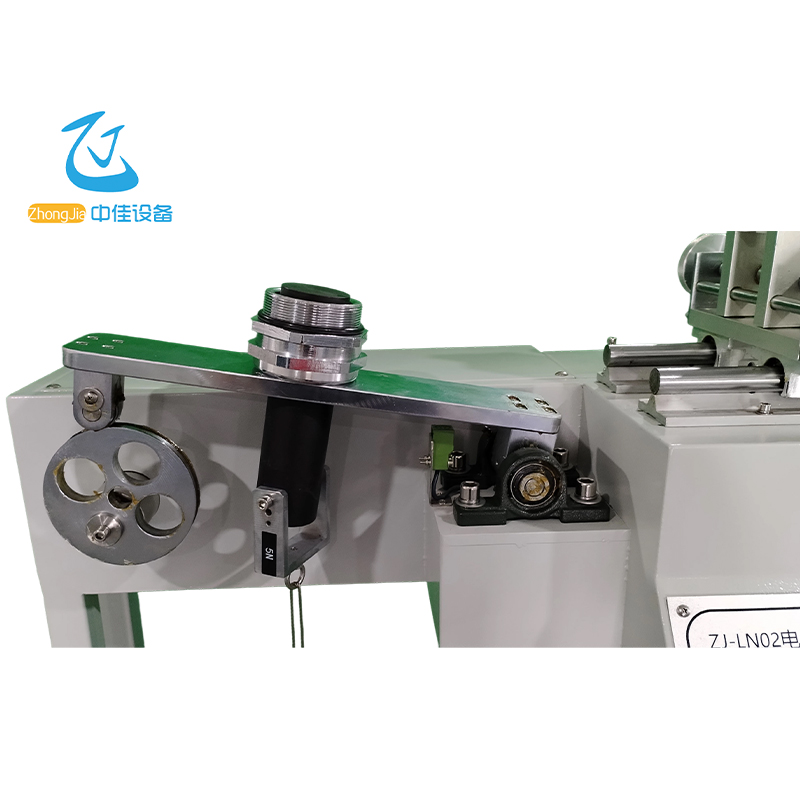

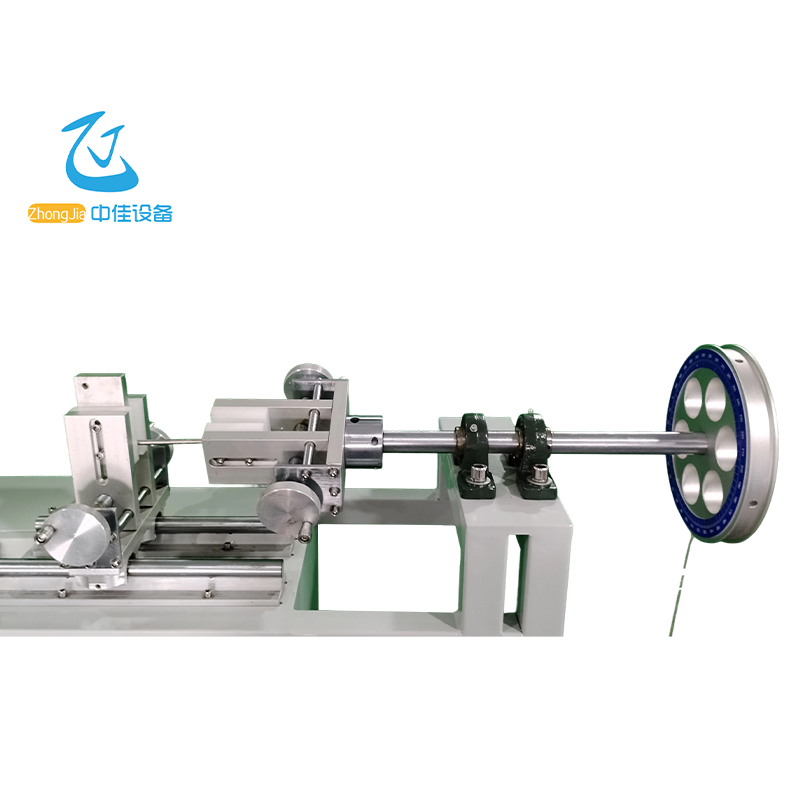

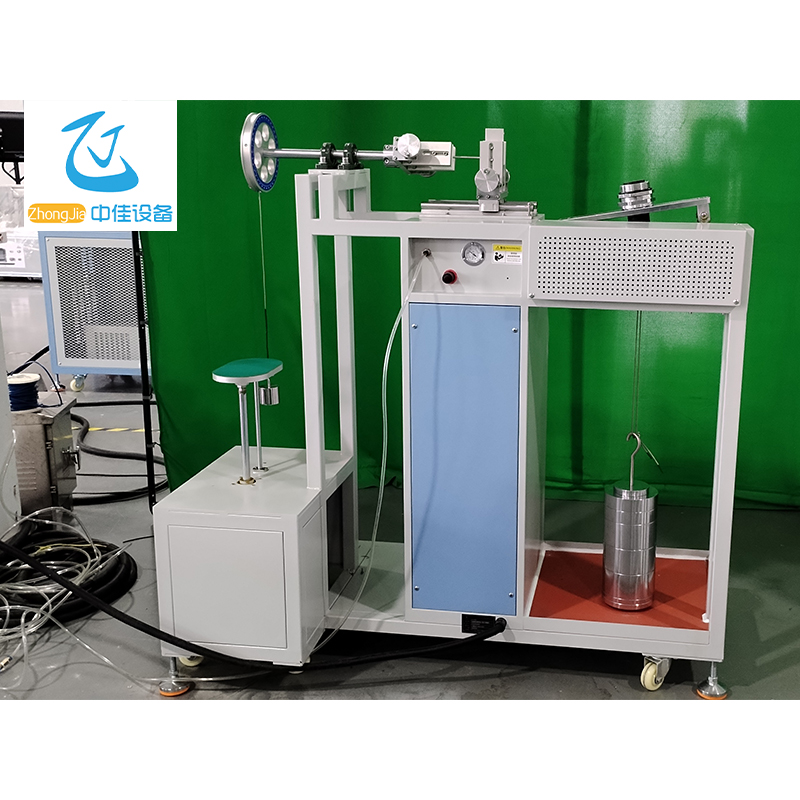

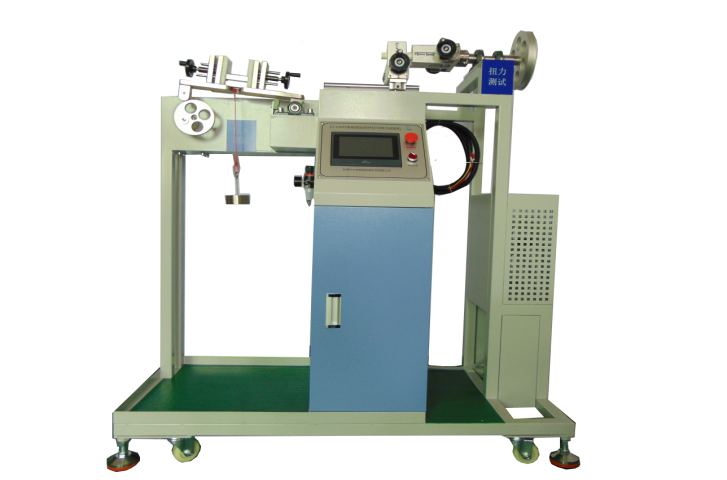

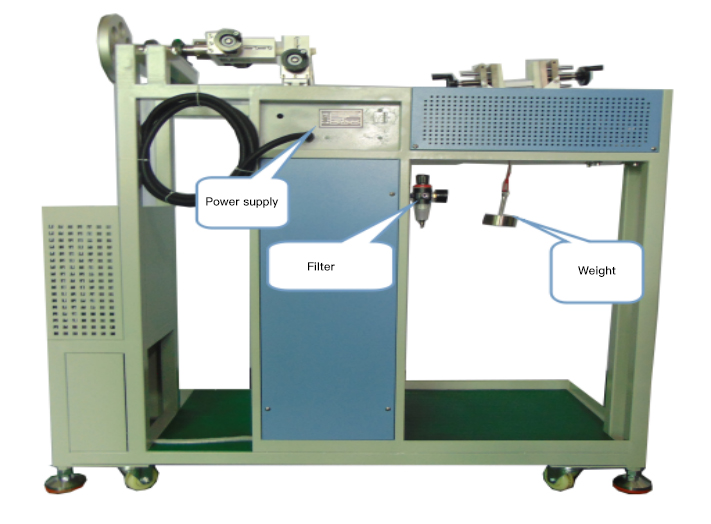

1 | The whole machine is welded by sheet metal, the surface is painted, and the panel is made of aluminum plate with sandblasting and silk screen printing. |

2 | Working power supply: three-phase AC380V 50HZ; |

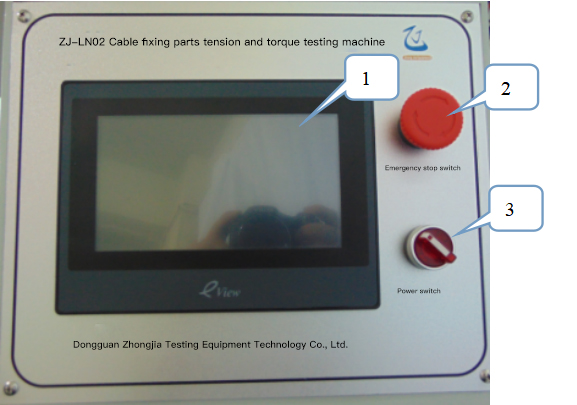

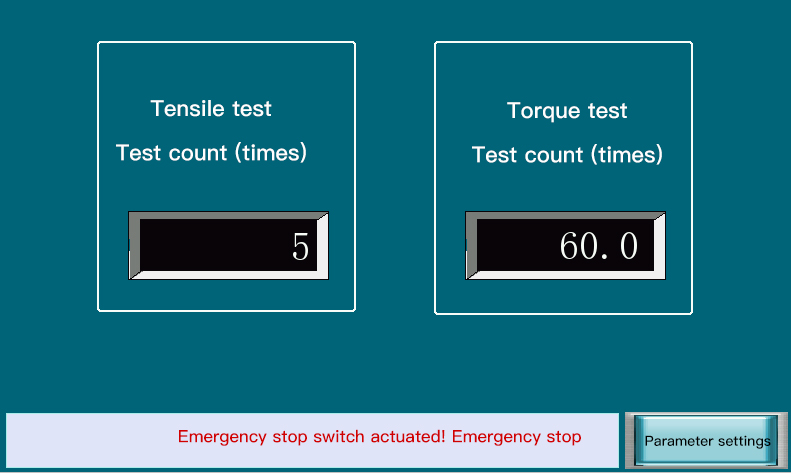

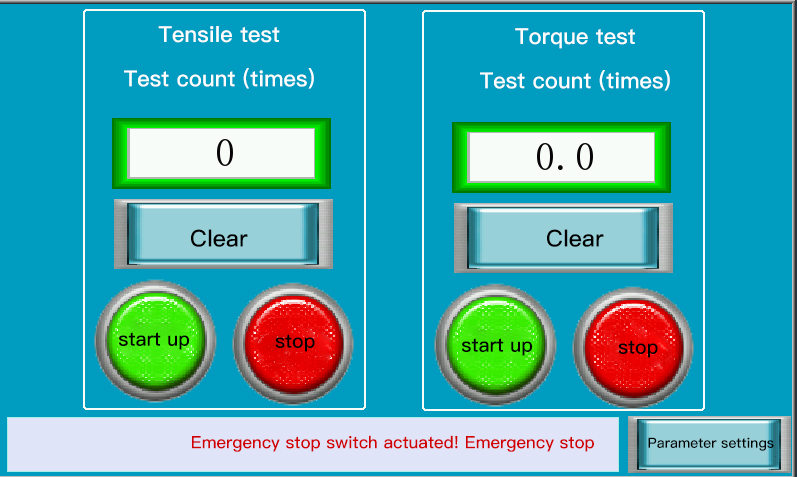

3 | Equipment control mode: Panasonic PLC + touch screen control; |

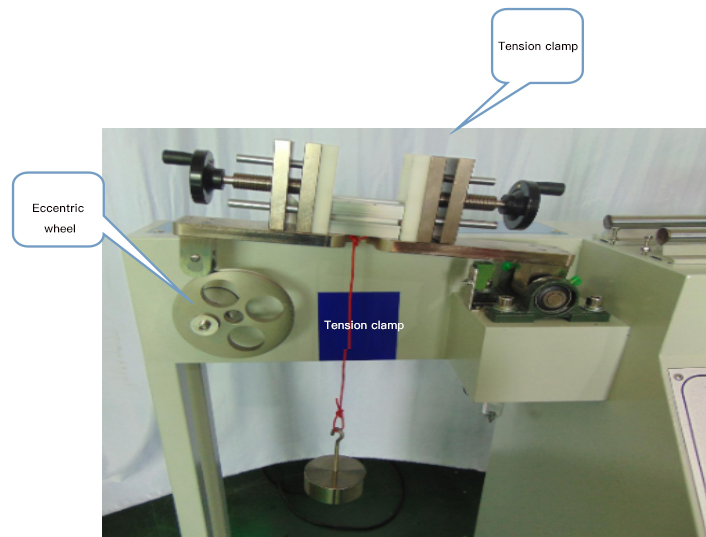

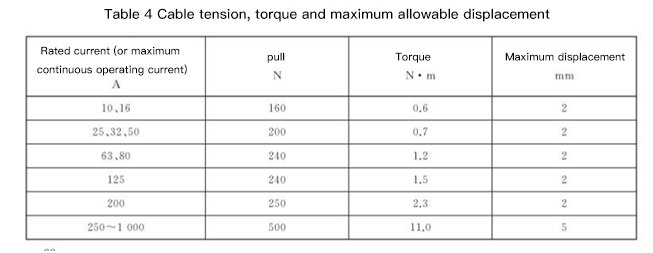

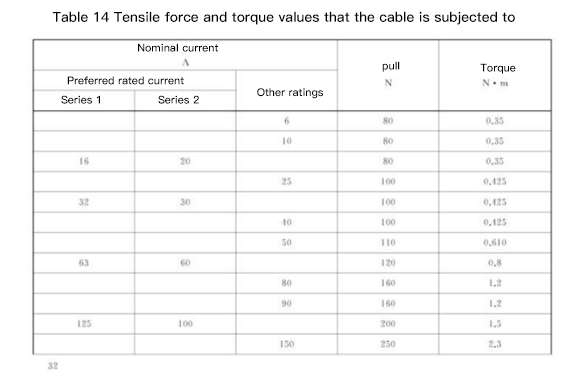

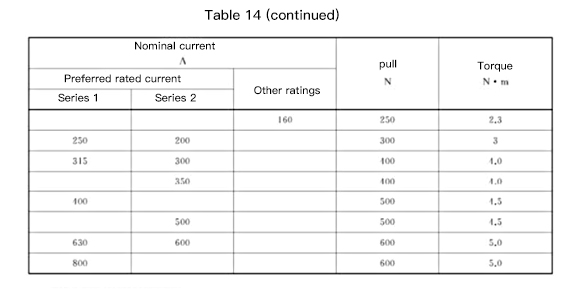

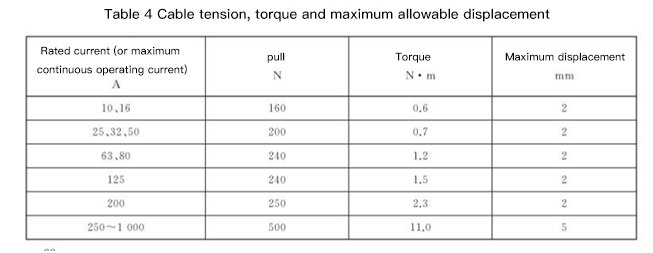

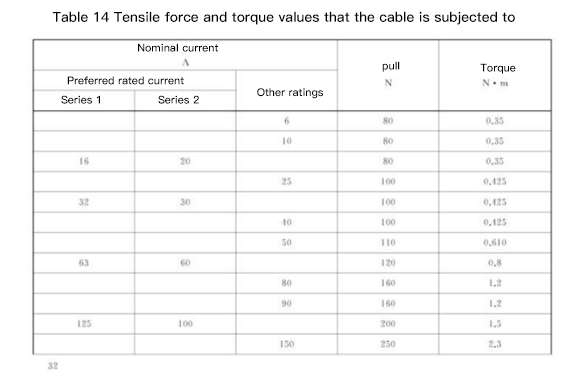

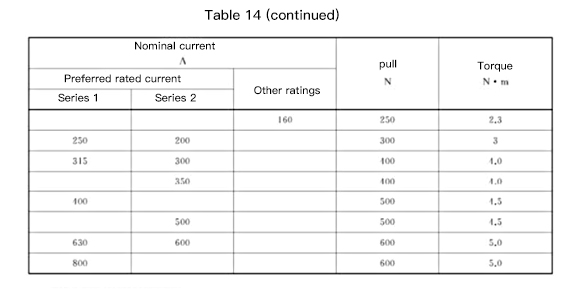

4 | Tensile force: can be combined into 80N, 100N, 110N, 120N, 160N, 200N, 240N, 250N, 300N, 400N, 500N, 600N. |

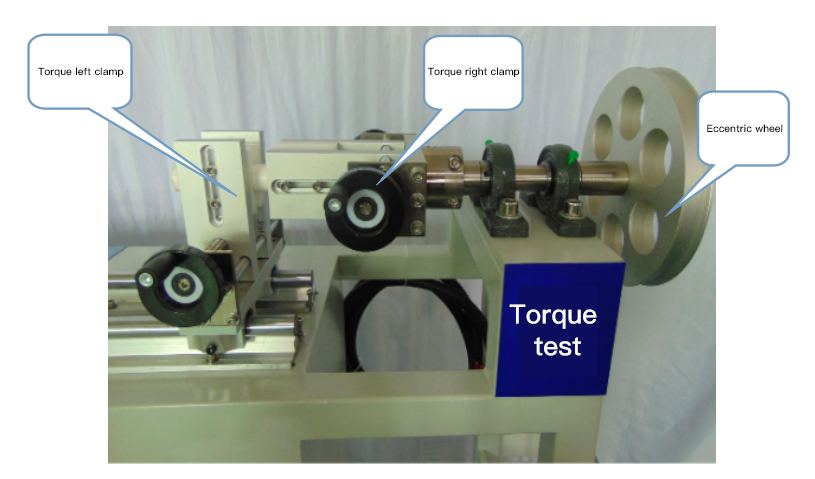

5 | Torque: 0.6Nm, 0.7Nm, 1.2Nm, 1.5Nm, 2.3Nm, 11Nm, 0.35 Nm, 0.425 Nm, 0.61 Nm, 0.8 Nm, 3 Nm, 4.0 Nm, 4.5 Nm, 5.0 Nm of torque can be achieved. |

6 | Test times: 0 to 999999 times adjustable |

7 | Tensile frequency: 1 time/second |

8 | Torque time: 1min~99H99M99S |

9 | Dimensions: 1300x800x1400mm. |

10 | Test data is set on the touch screen |

11 | With power-off data storage memory function. |

12 | Meet the following form requirements:

|

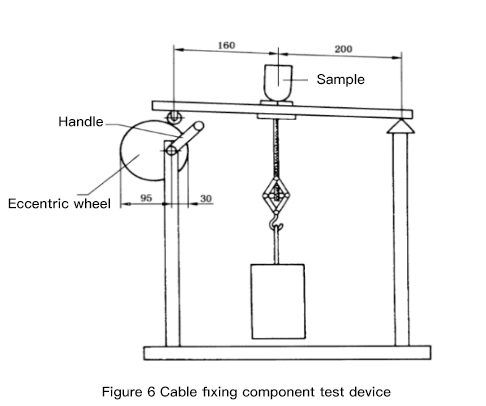

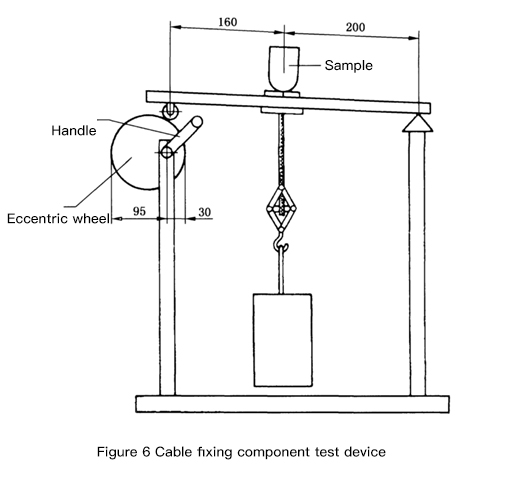

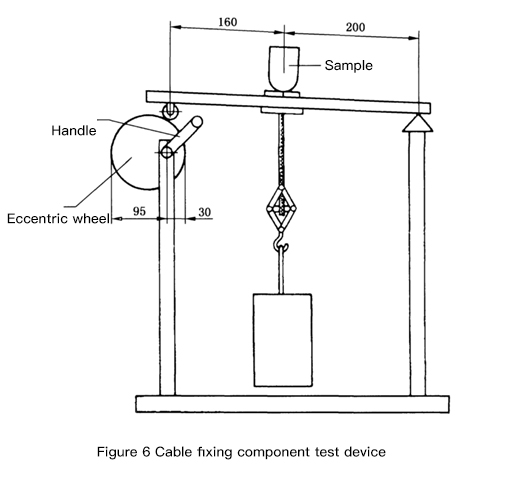

13 | The equipment meets the requirements of Figure 6

|