Serial number | Technical Parameters |

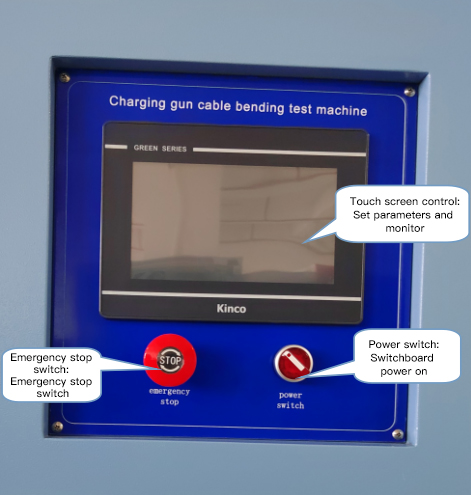

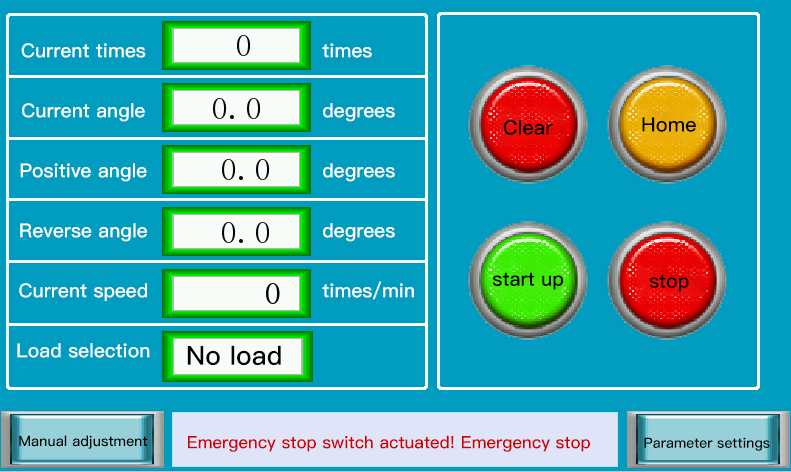

1 | Control system: imported 7-inch human-machine interface (true color LCD touch screen), Panasonic programmable controller (PLC) |

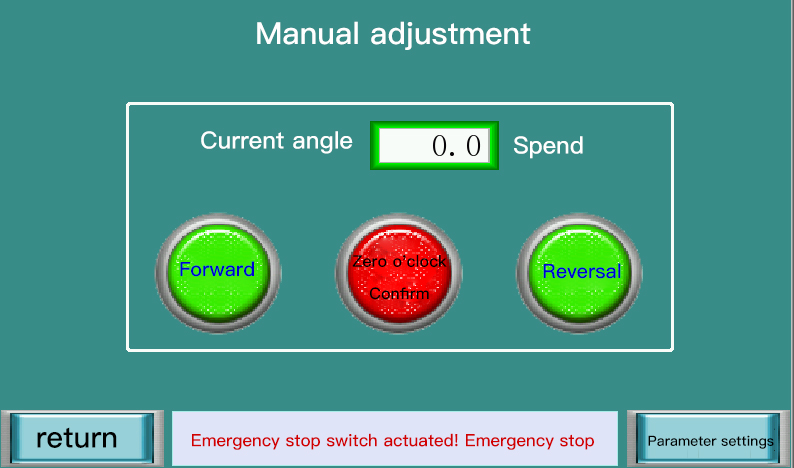

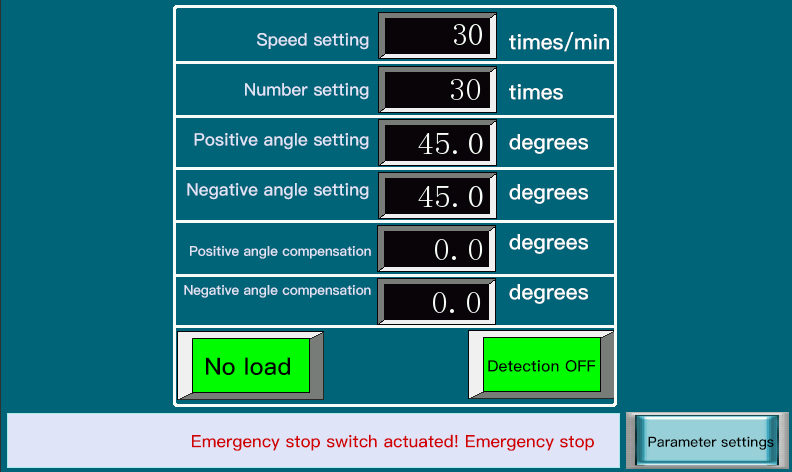

2 | Screen settings and display information: parameter monitoring, angle setting, speed pre-adjustment, count setting, alarm indication and character prompts, etc. |

3 | Test station: single station |

4 | The program can set the experiment of single station or any station by itself |

5 | Test rate: can be set and intelligently adjusted (0-80 times/minute (one round trip counts as one time) |

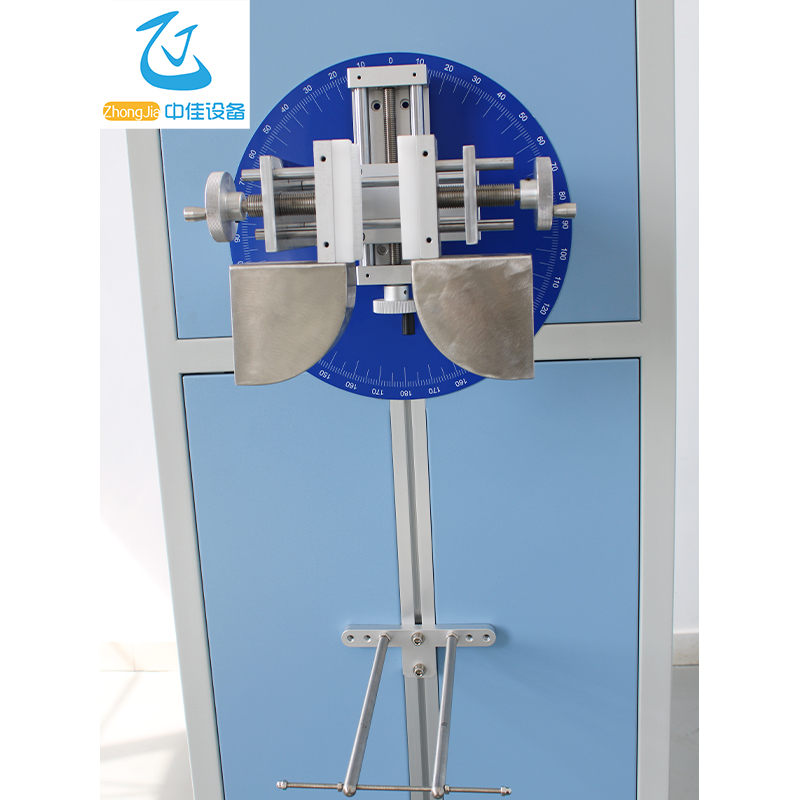

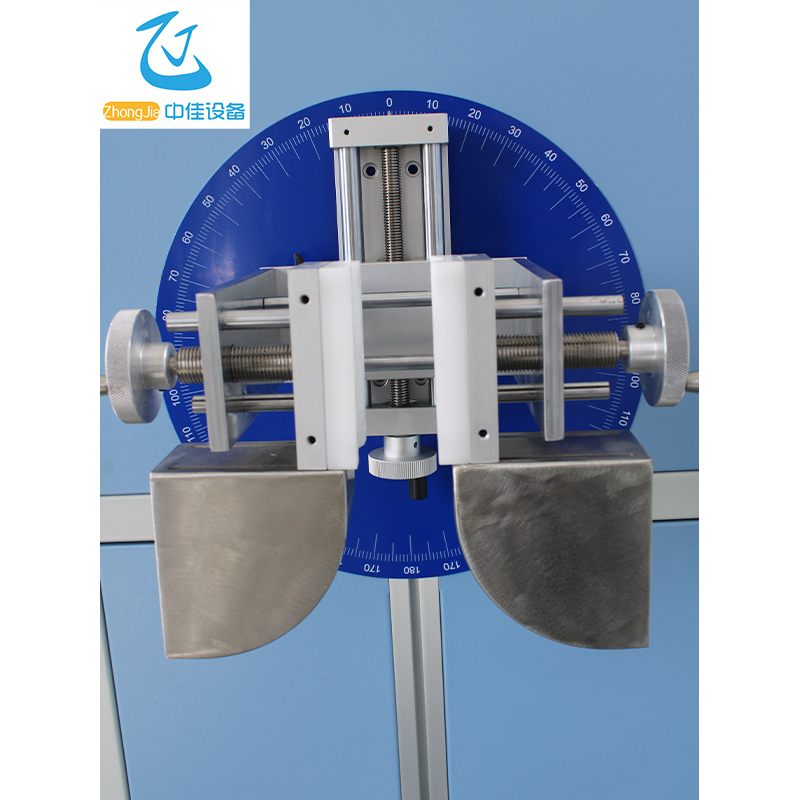

6 | Test bending rotation angle: can be set and intelligently adjusted (left and right angles 0~180 degrees test angle can be preset) |

7 | Total angle*speed is less than 5400 |

8 | Counter: 0 to 9999999 times can be preset, with power failure memory function |

9 | Weight: The configured weights can be combined into 20N, 25N, 50N, 75N, 100N, 120N/140N/180N; |

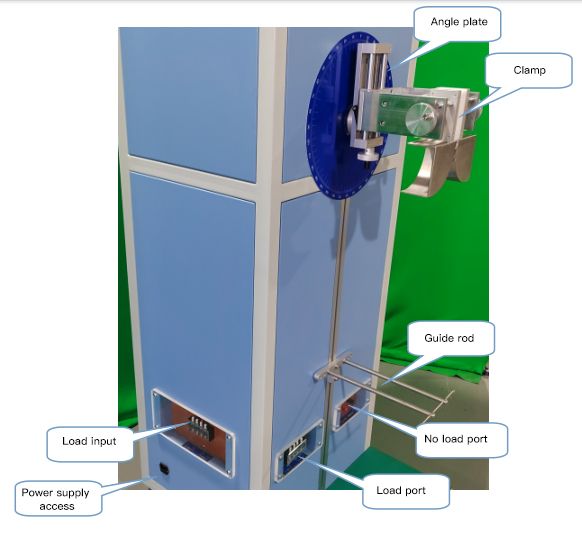

10 | Material A3, surface plating |

11 | Reserved load access port current ≥ 800A |

12 | External pointer displays the bending angle from 0 to 360 degrees |

13 | With disconnection detection function |

14 | Powertrain: servo motor + turbine reducer |

15 | Test cable range: diameter 5~70mm |

16 | 1 set of fixing bracket with wires for easy installation of wire clips |

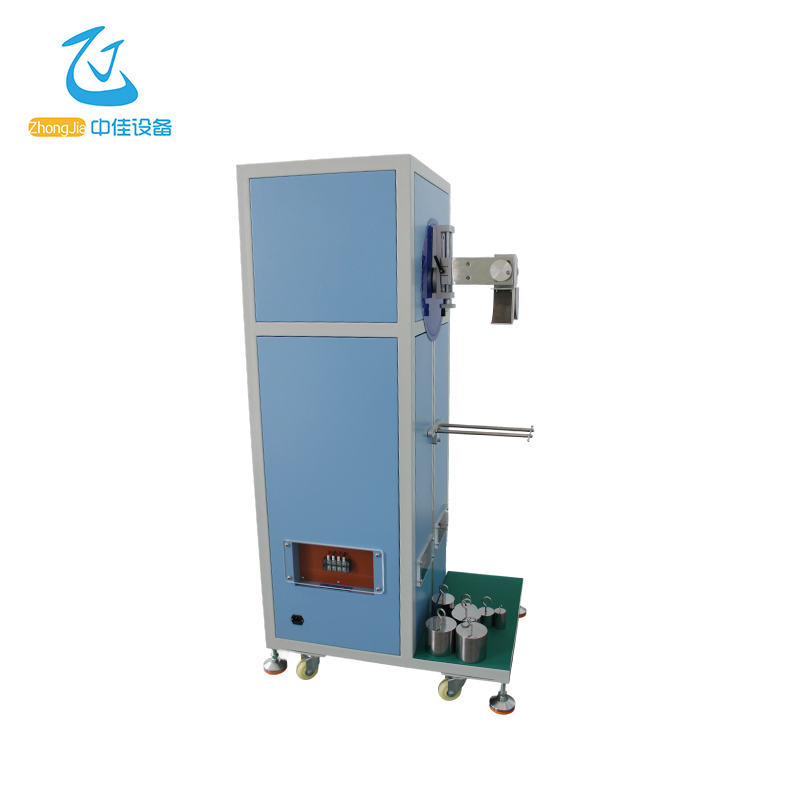

17 | Dimensions: about W950*D650*H1600mm |

18 | Weight: Approx. 220Kg |

19 | Power supply voltage: AC220V±5%, 50Hz10A |

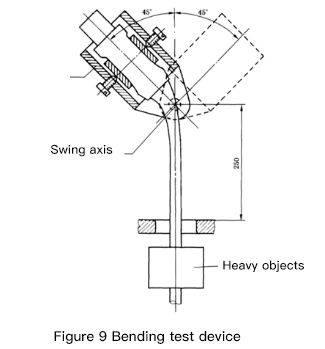

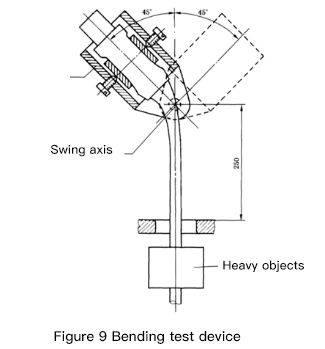

20 | The equipment meets the requirements of Figure 9

|

Serial number | Technical Parameters |

1 | The whole machine is welded by sheet metal, the surface is painted, and the panel is made of aluminum plate with sandblasting and silk screen printing. |

2 | Working power supply: three-phase AC380V 50HZ; |

3 | Equipment control mode: Panasonic PLC + touch screen control; |

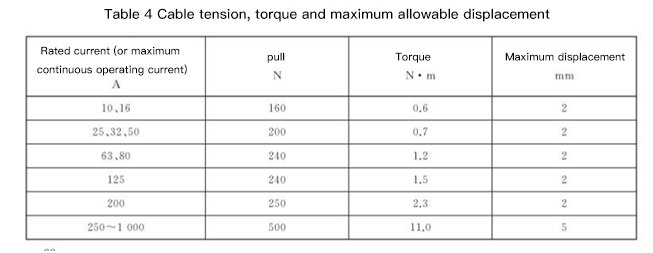

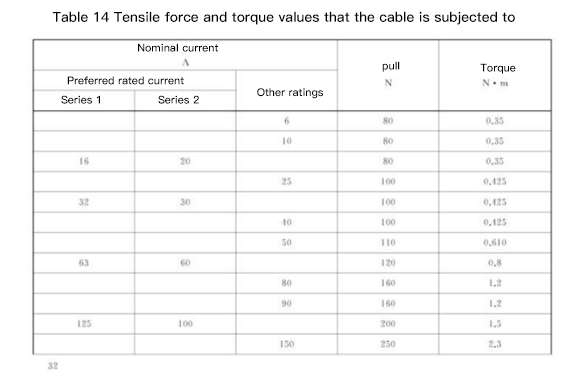

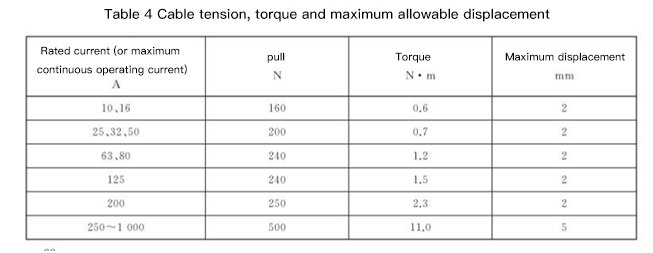

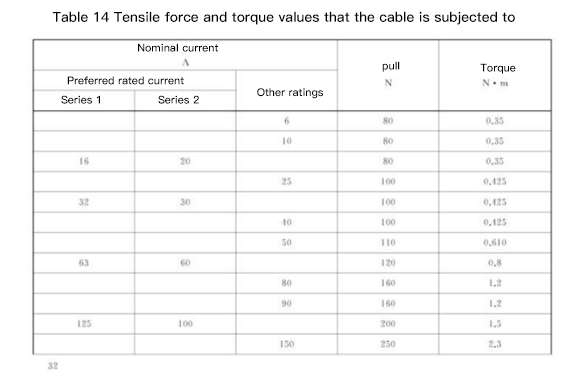

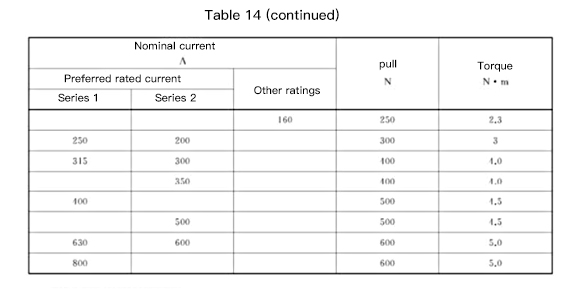

4 | Tensile force: can be combined into 80N, 100N, 110N, 120N, 160N, 200N, 240N, 250N, 300N, 400N, 500N, 600N. |

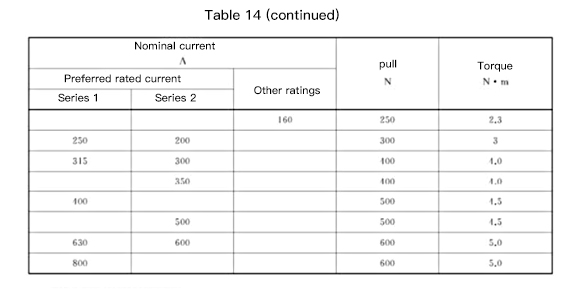

5 | Torque: 0.6Nm, 0.7Nm, 1.2Nm, 1.5Nm, 2.3Nm, 11Nm, 0.35 Nm, 0.425 Nm, 0.61 Nm, 0.8 Nm, 3 Nm, 4.0 Nm, 4.5 Nm, 5.0 Nm of torque can be achieved. |

6 | Test times: 0 to 999999 times adjustable |

7 | Tensile frequency: 1 time/second |

8 | Torque time: 1min~99H99M99S |

9 | Dimensions: 1300x800x1400mm |

10 | Test data is set on the touch screen |

11 | With power-off data storage memory function |

12 | Meet the following form requirements:

|

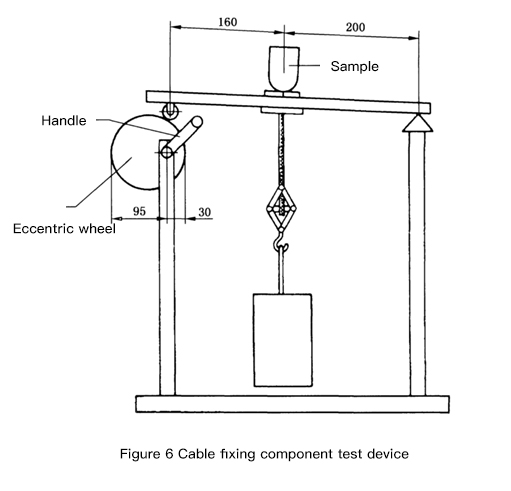

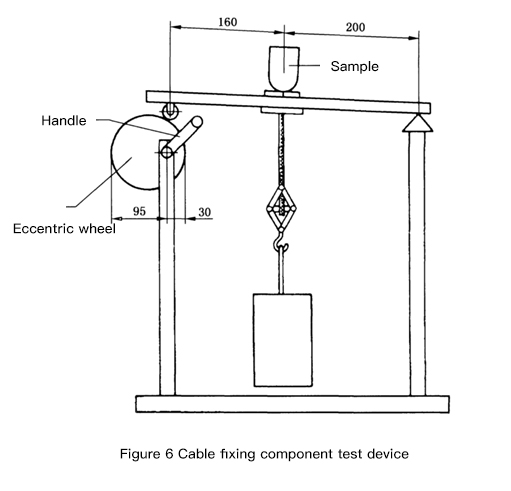

13 | The equipment meets the requirements of Figure 6

|