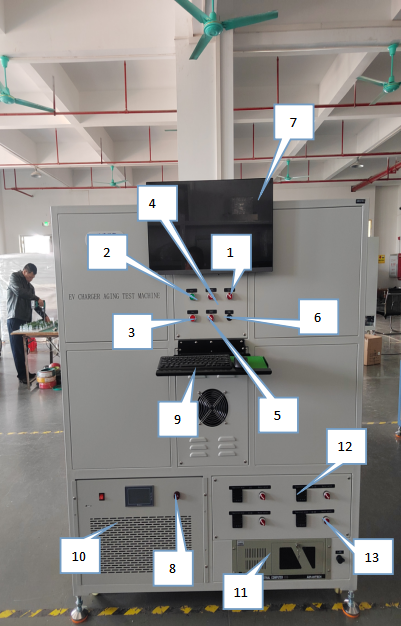

EV Charger Aging Test Machine(With High Temperature Box)

HHLH-820C

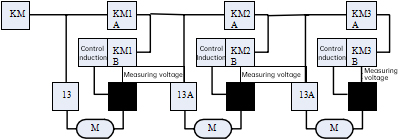

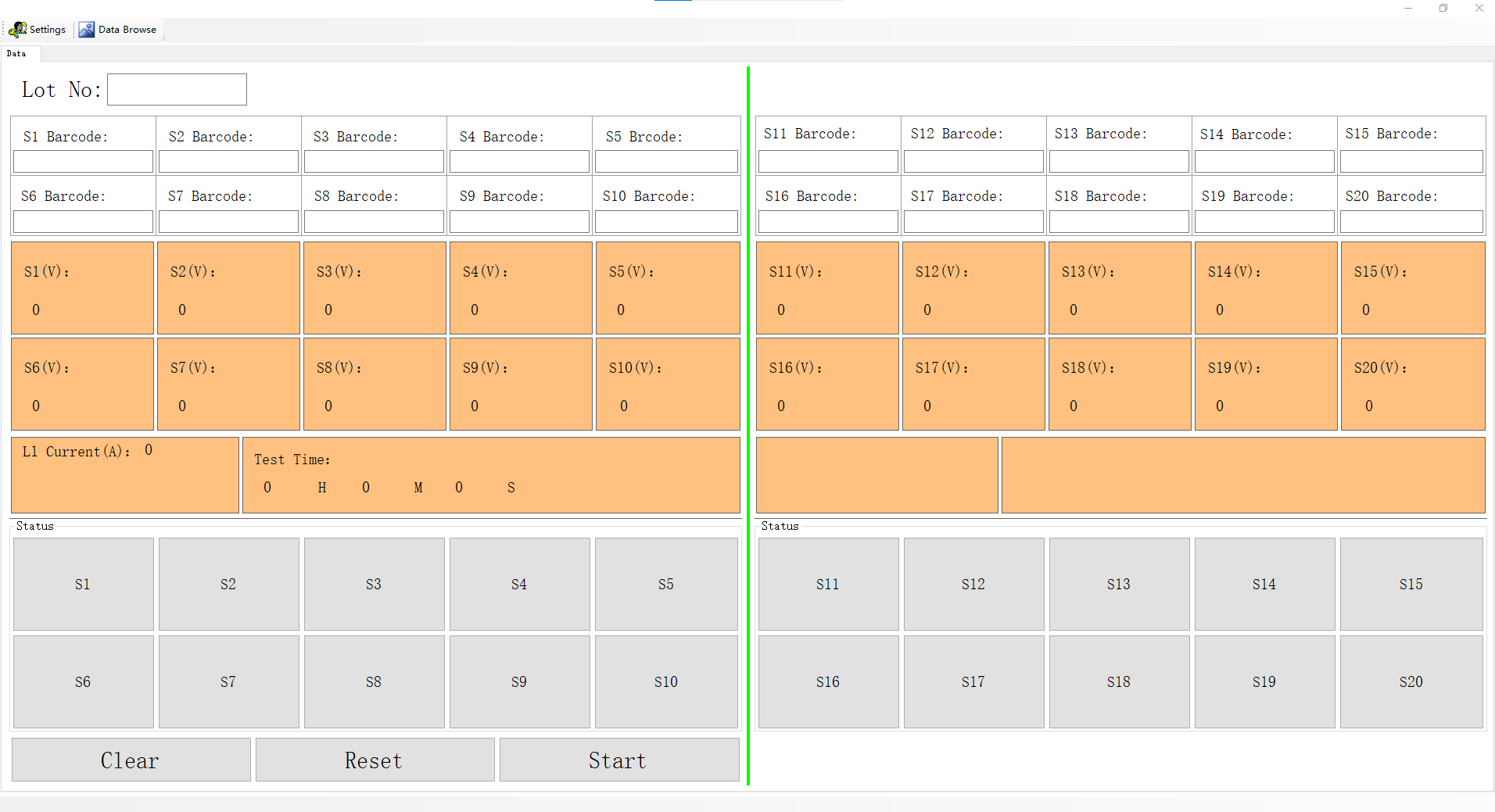

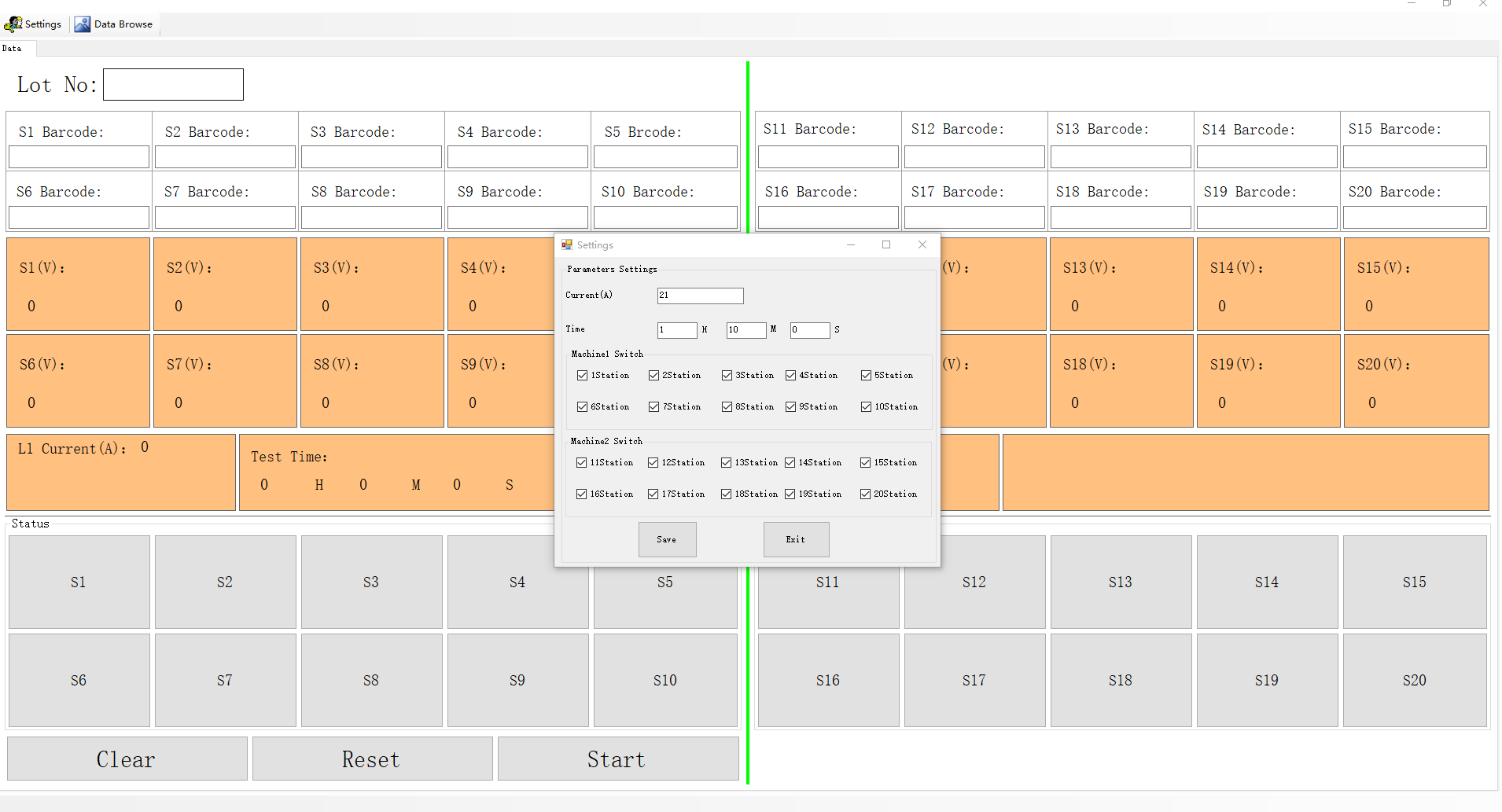

This AC charging gun aging tester adopts advanced computer control and energy-feeding load, and the test system is more intelligent, energy-saving and environmentally friendly.

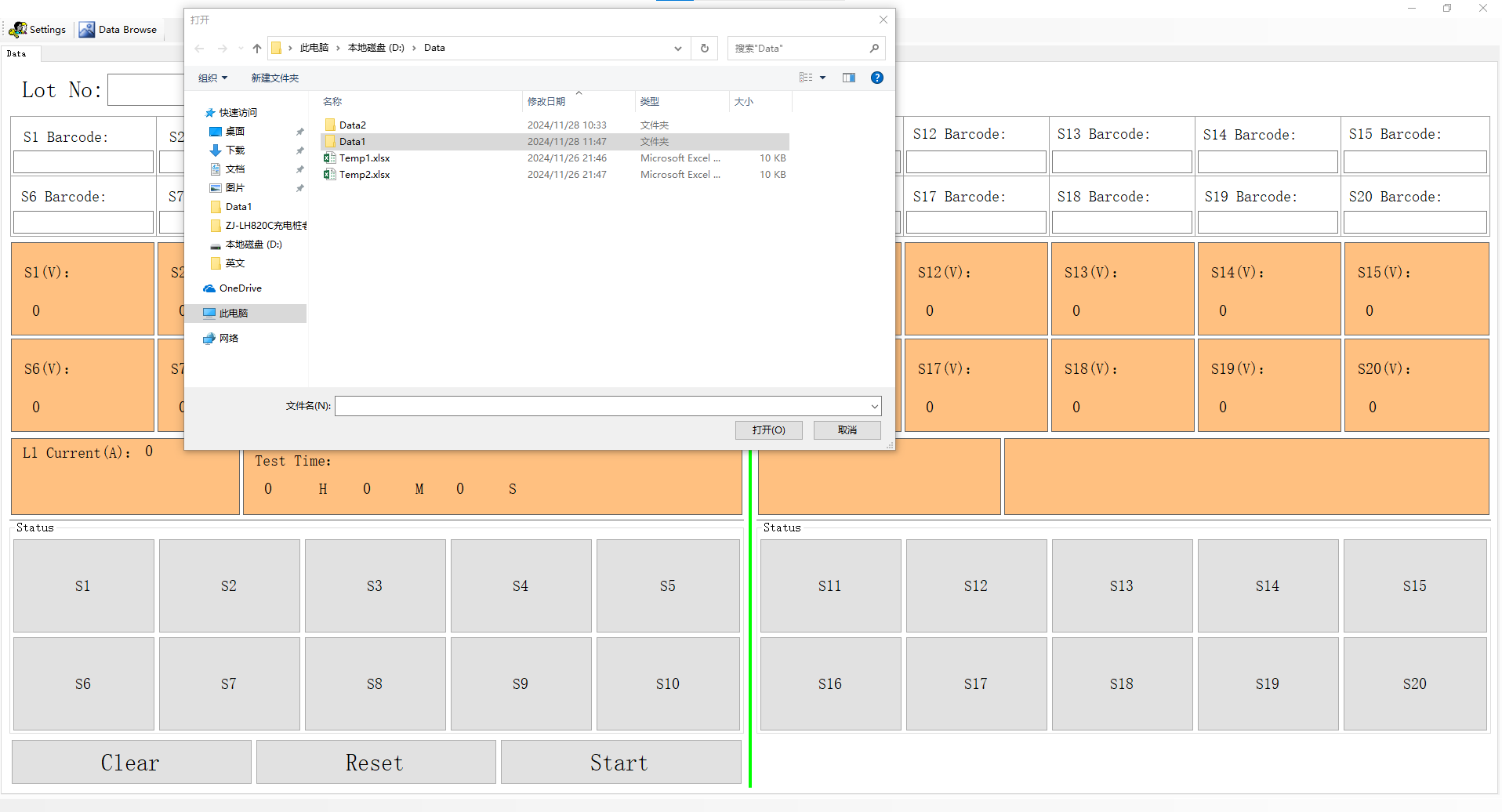

1) Intelligence: The software automatically monitors aging, automatically cuts off the power supply and prompts alarm information when it fails or is defective

The equipment automatically short-circuits the faulty sample, and other stations continue to test

2) Energy saving: The energy-feeding load is used to achieve energy recovery to achieve energy saving

3) Environmental protection: The power is fed back to the power grid, which does not generate a lot of heat and avoids the increase of the ambient temperature of the test site

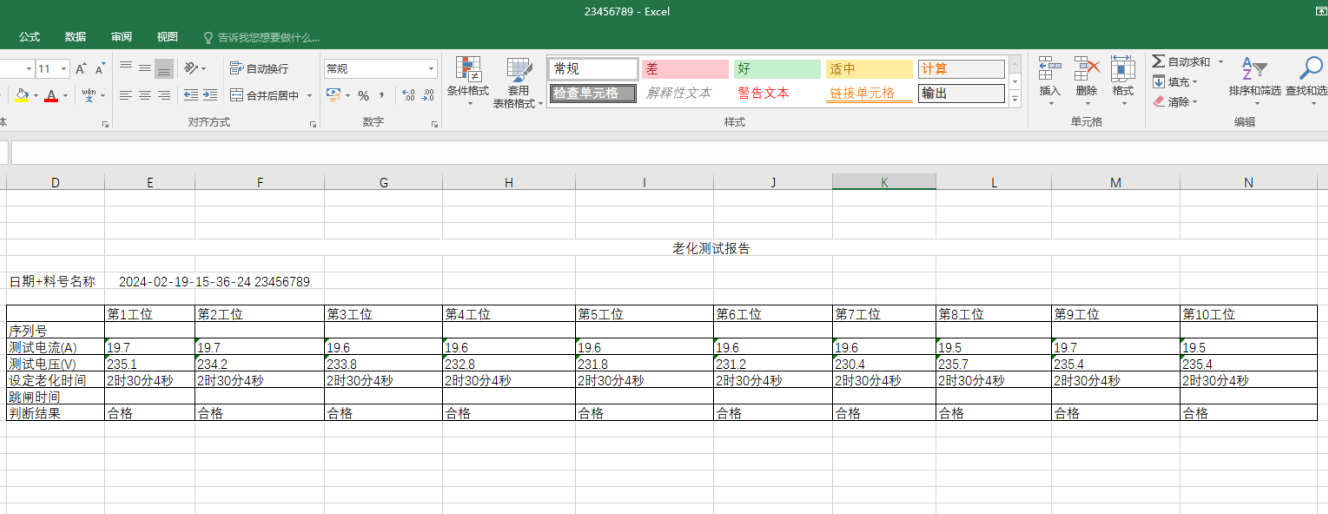

4) Traceability: The test data can be queried and traced in real time