- Home

-

Our Services

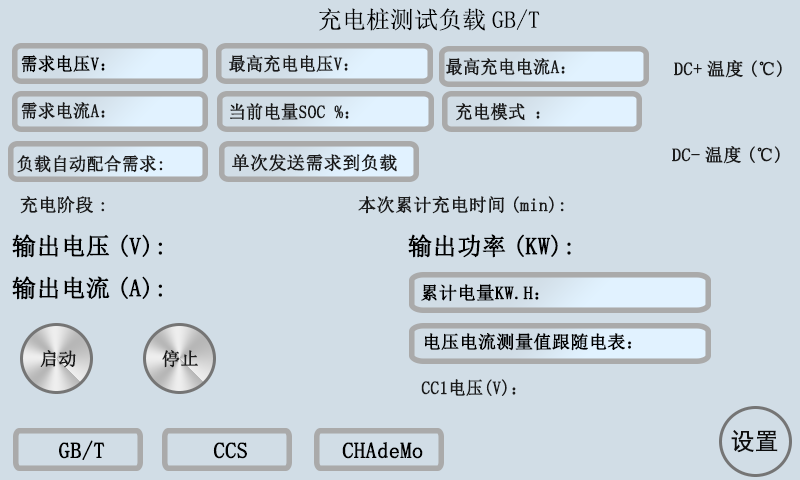

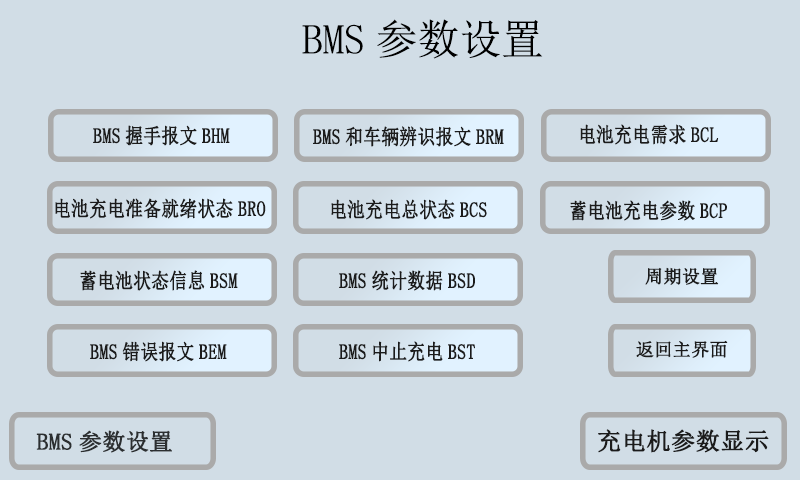

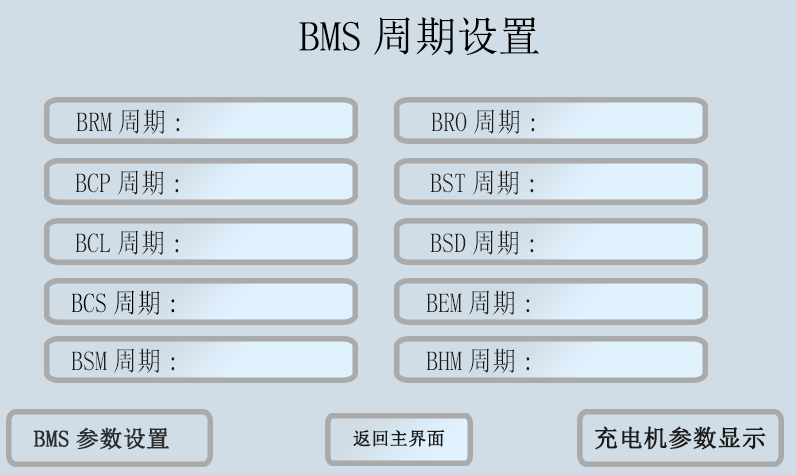

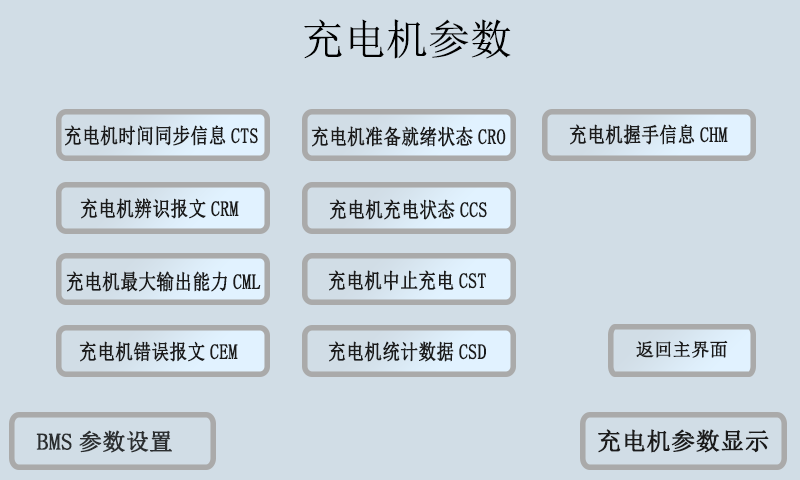

- Charging Gun Pile Testing Equipment

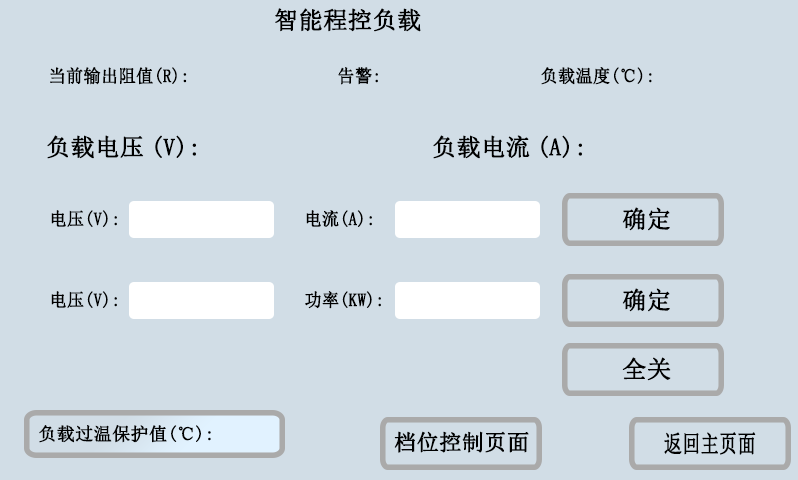

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

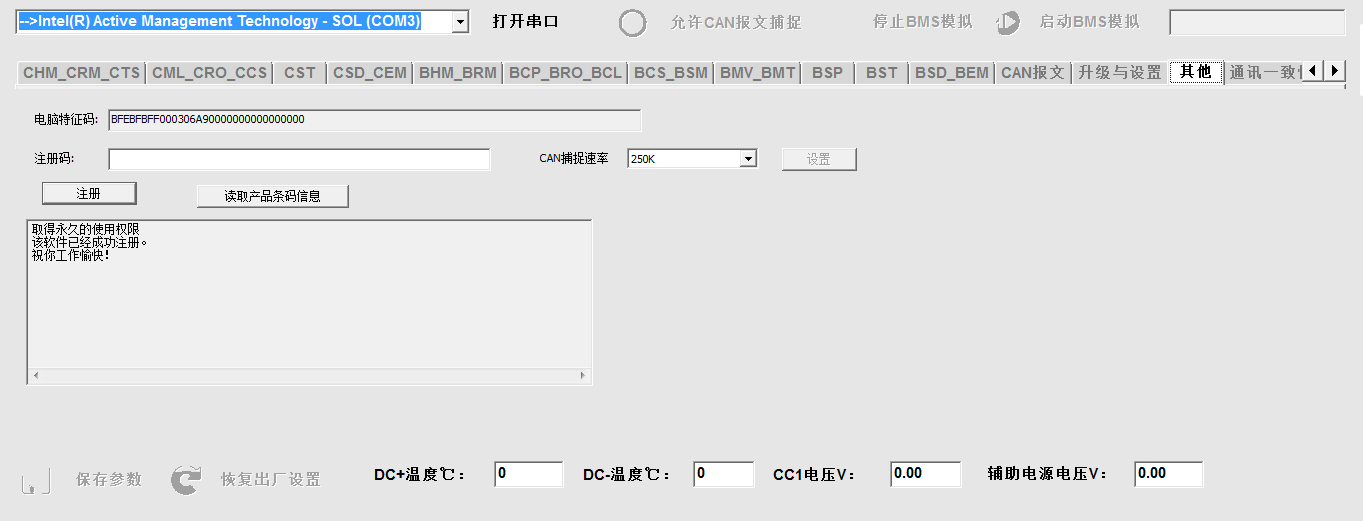

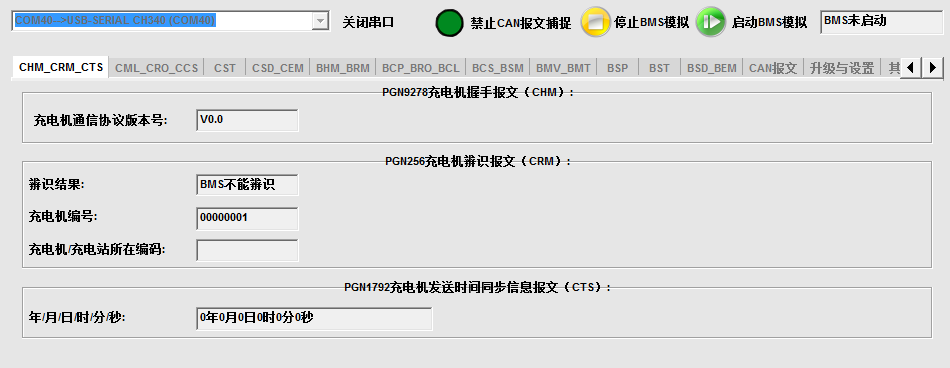

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

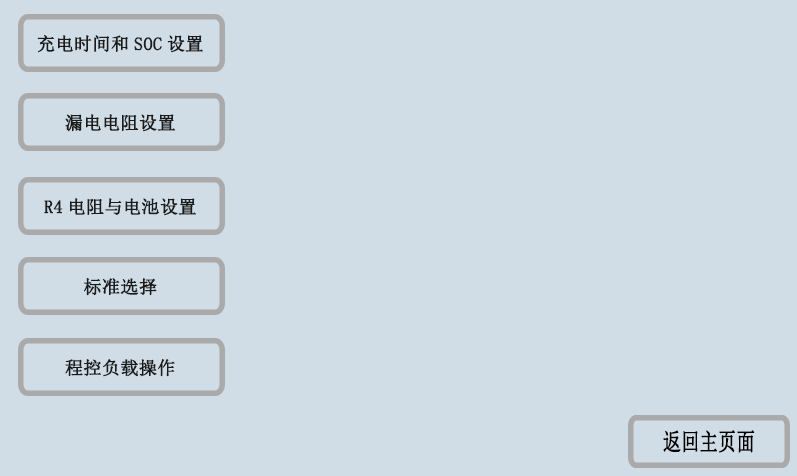

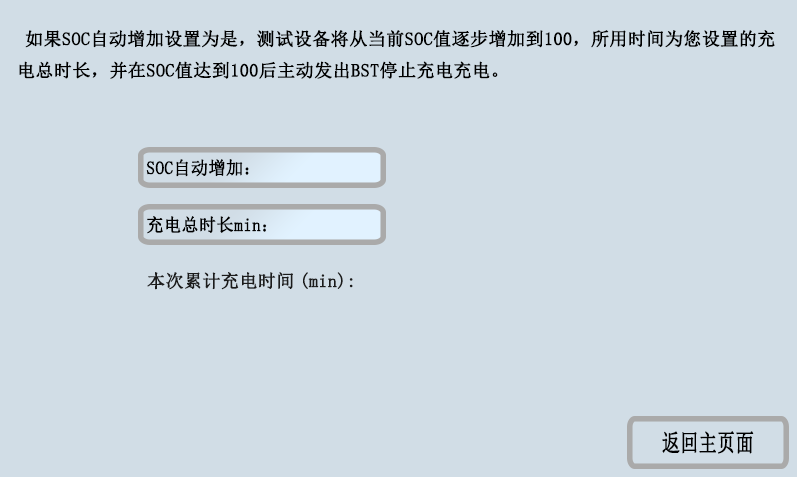

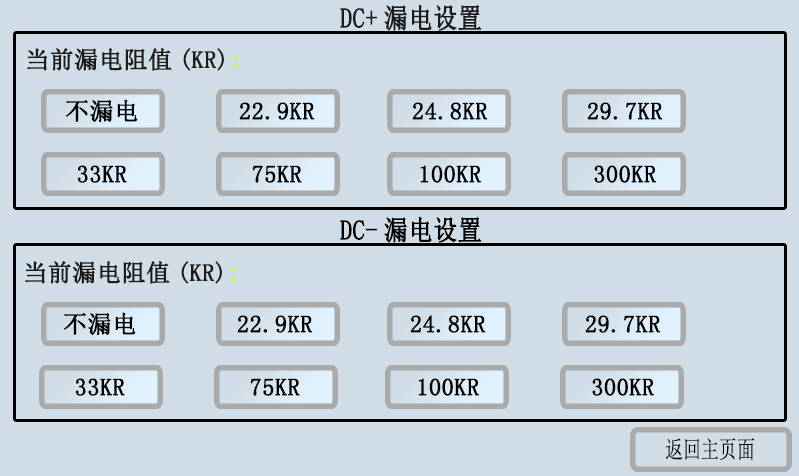

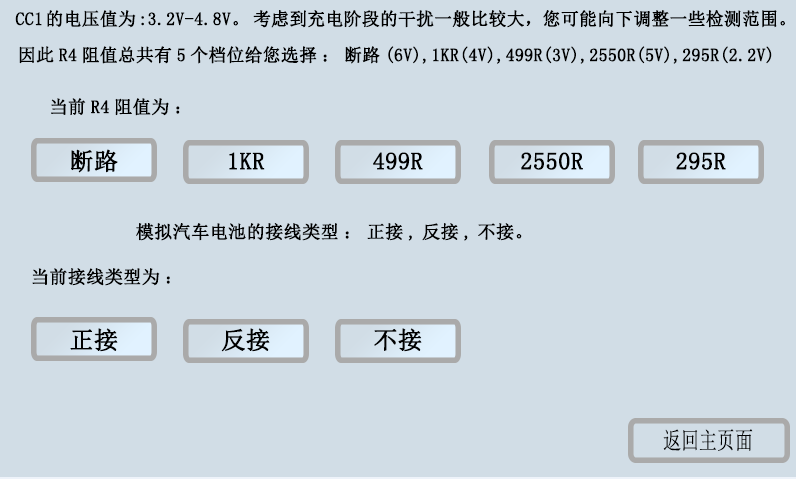

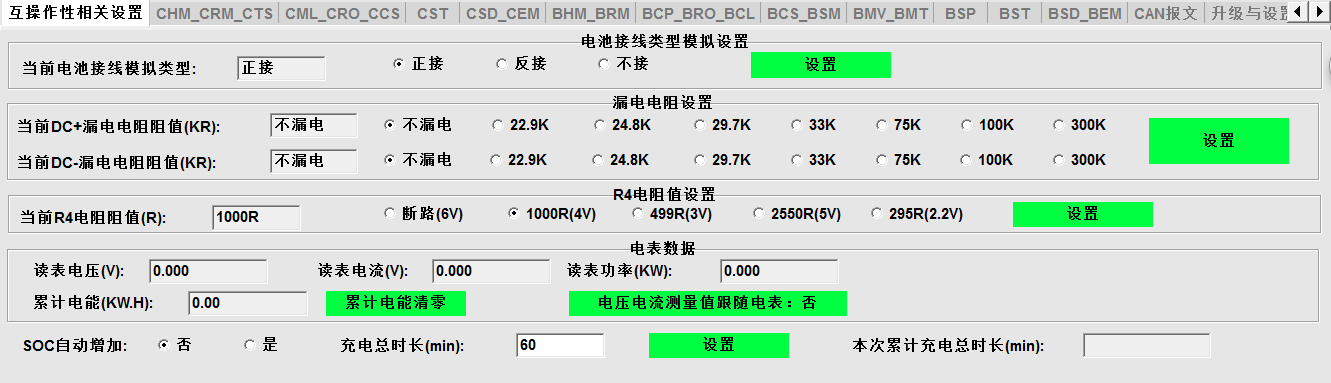

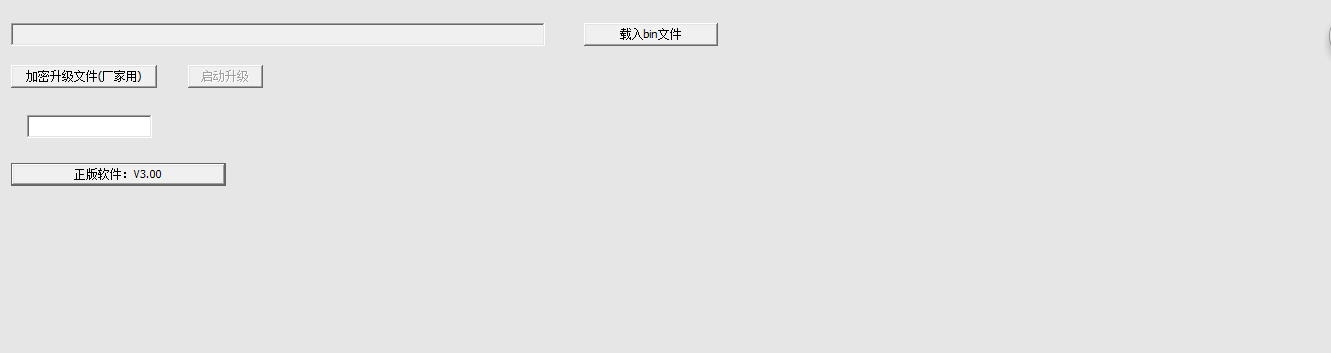

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Charging Gun Pile Testing Equipment

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Display

- News

- About

- Contact Us

- Partners