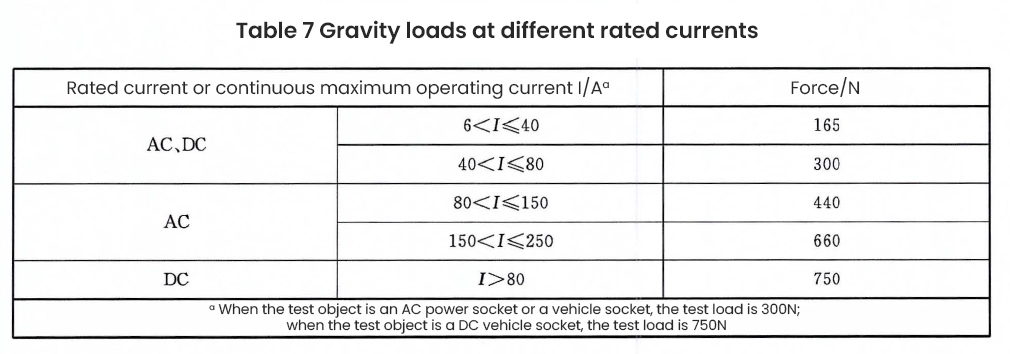

Serial number | Technical Parameters |

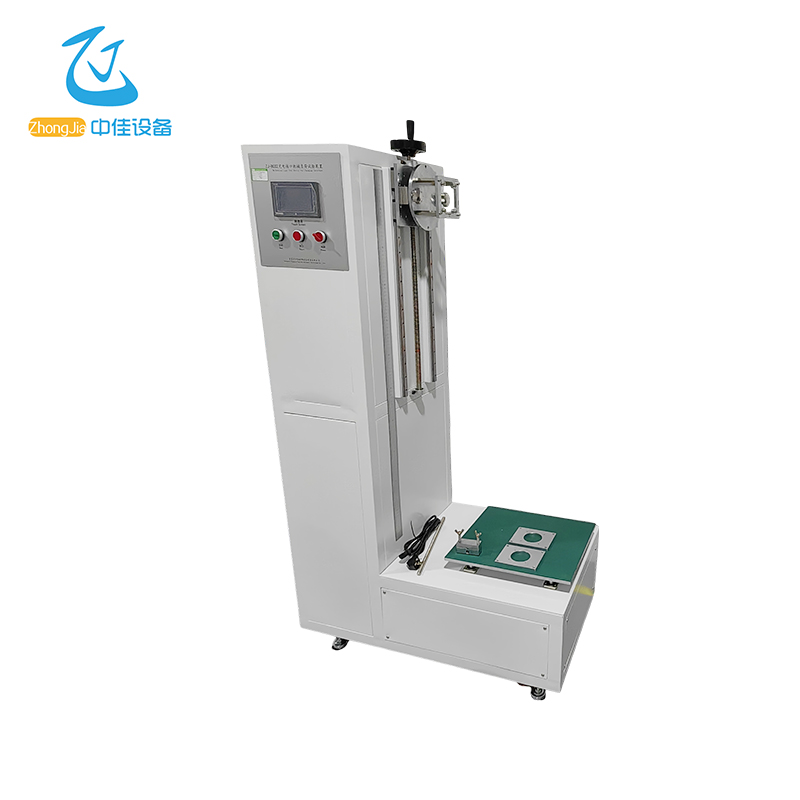

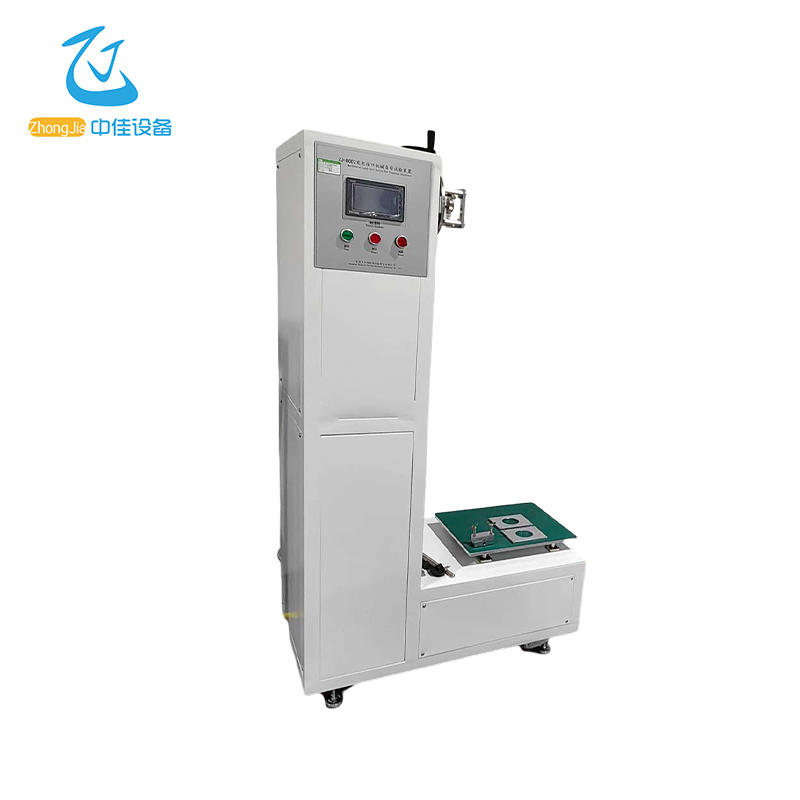

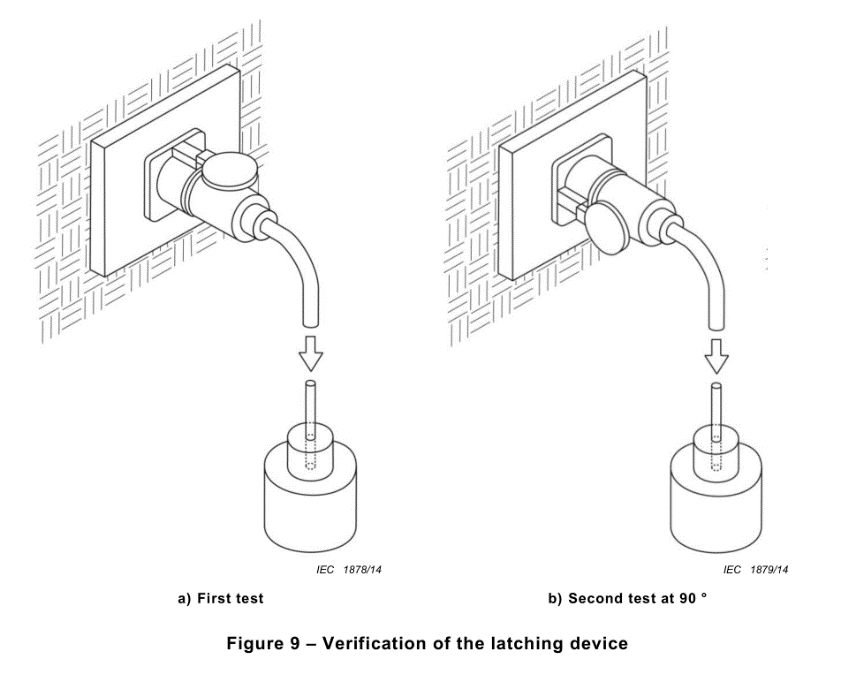

1 | The equipment meets the gravity load requirements of Table 7. The gun mount can be manually rotated 90 degrees, the cylinder lifts and releases the weight, and the force is automatically timed. |

2 | Control device: cylinder, PLC, touch screen |

3 | Equipped with national standard, European standard and American standard gun mount and fixing plate. |

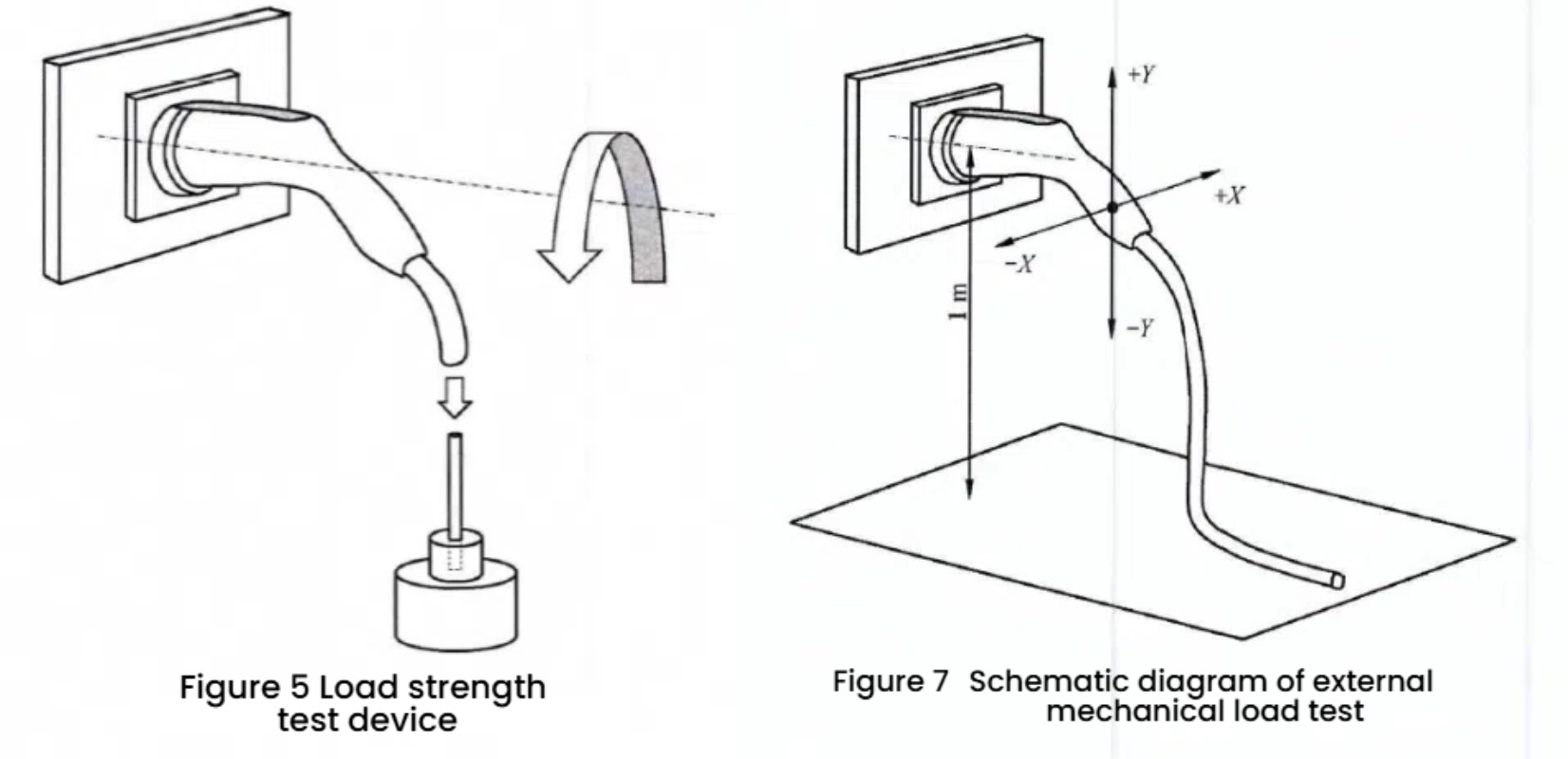

4 | The power supply plug or vehicle plug is made of hardened steel with a finely ground contact, the surface roughness of which does not exceed 0.8μm over its working length, and the spacing is the nominal distance with a tolerance of ±0.05mm. For other types of plugs, the size of the plug or the distance between the plug surfaces shall comply with the minimum size given in the relevant standards, with a tolerance of +0.01mm and 0mm (no negative tolerance) |

5 | The total weight of the test supply plug or test vehicle plug, the clamping device, the load-bearing device, the main weight and the additional weight shall exert a withdrawal force in accordance with Table 7. The weight of the additional weight shall be such that the force exerted is equal to one tenth of the withdrawal force. The main weight shall be hung on the test plug without shaking, and then the additional weight shall be dropped from a height of 5 cm onto the main weight. |

6 | The gun mount can be manually rotated 90 degrees, 180 degrees, and 270 degrees. |

7 | The height of the gun mount can be adjusted manually, and the upper and lower heights can be adjusted from 0.5m to 1.5m. |

8 | Meet the tensile force requirements of 100N, 165N, 300N, 440N, 660N, 750N combinations and can be applied continuously for more than 1 min |

9 | Automatic force timing: 0~999.9s |

10 | Automatic counting of force application times: 0~999 |