-

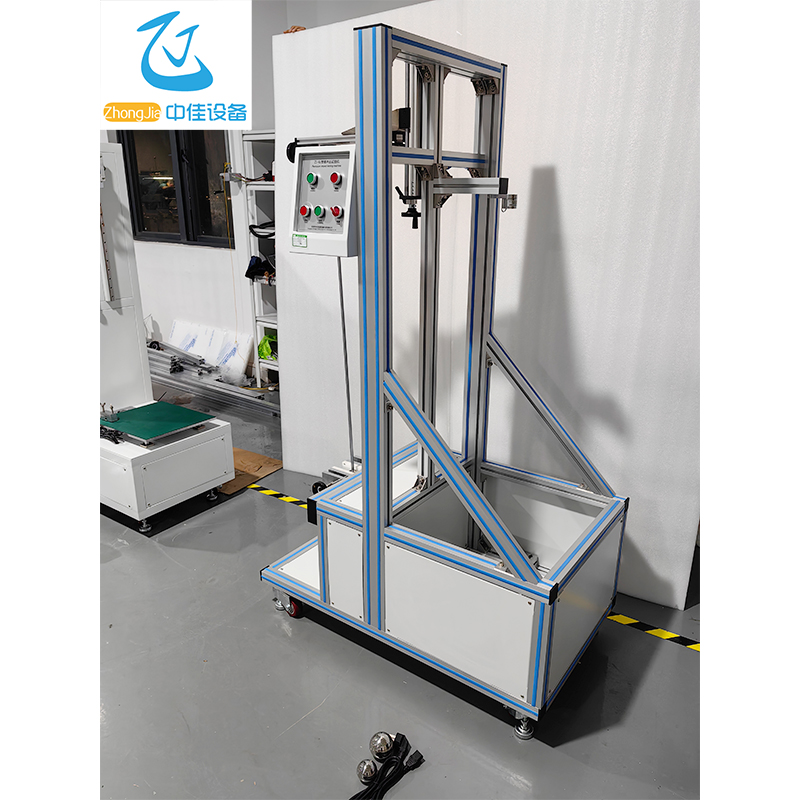

Pendulum Impact Testing Machine

ZJ-4J

Send Email Details

The equipment must meet the test requirements of clauses 6.2.10.2 and 7.11.2 of GB/T 20234.1-2023, and is applicable to mechanical strength tests and drop ball impact tests of vehicle plugs, sockets, vehicle connectors and vehicle jacks. The mounting bracket is adjustable up and down, left and right. The swing arm is adjustable front and back, left and right, and the angle is adjustable, with a foot cup at the bottom. -

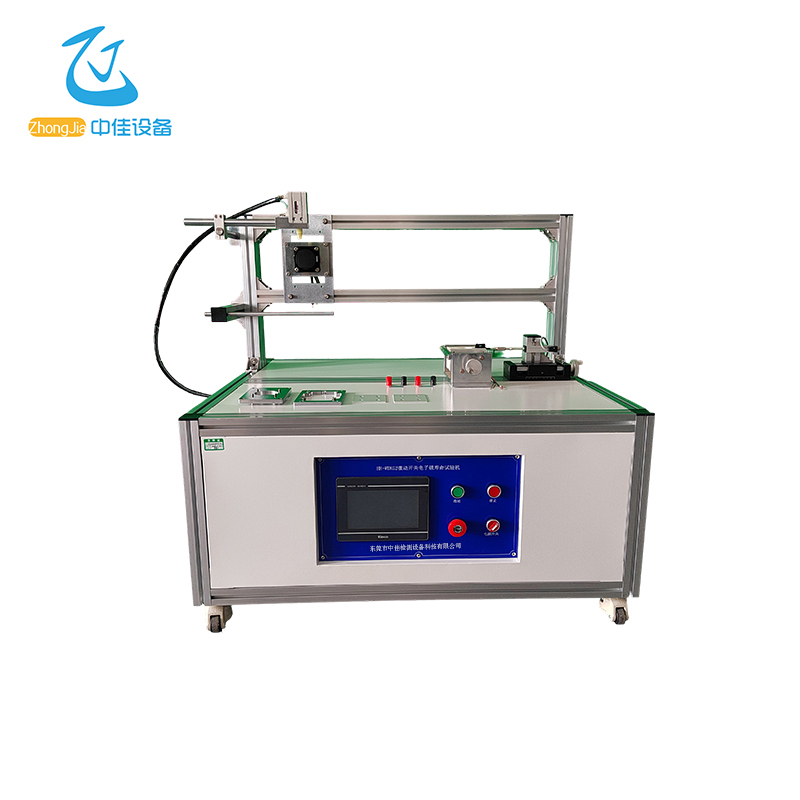

Charging Gun Electronic Locking Device Comprehensive Testing Machine

ZJ-AJ01

Send Email Details

The device meets the test requirements of GB/T18487.1-2023 Clause 10.6, GB/T 20234.1-2023 Clauses 6.3.4 and 7.15.2, and IEC EN 62196-1-2022 Chapter 14, and is suitable for life testing of the electronic lock of the charging gun, with a foot pad at the bottom.

The electronic lock can be powered on and off, and the mechanical life of the electronic lock push rod extension and retraction, as well as the signal feedback life, the push rod is tested with the specified tension and thrust mode, and the mechanical lock is tested with external pressure. -

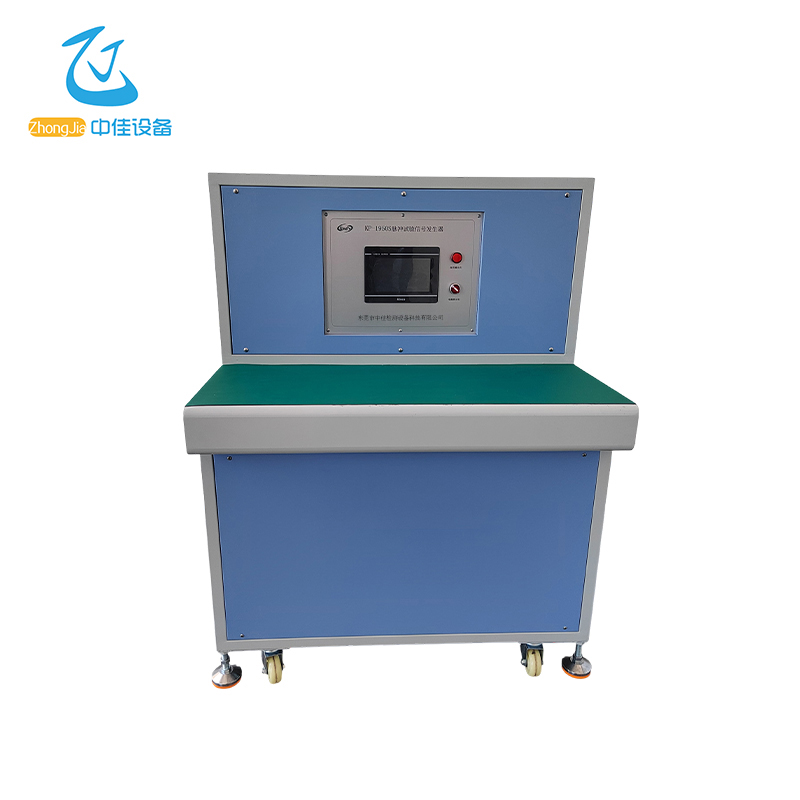

Residual Current Operated Circuit Breaker Tester

Type A/B

Send Email Details

The residual current operated circuit breaker tester is a leakage current testing device designed and developed by our company according to the requirements of electronic and electromagnetic leakage products.

The test bench is composed of relays, LCD screens, circuit boards, transformers and other components. It is controlled by a single-chip microcomputer and can automatically test the product according to the selected process. The equipment is easy to operate and has high testing efficiency. It is an ideal equipment for circuit breaker manufacturers to conduct batch rapid testing of circuit breakers. It is controlled by a single-chip microcomputer and can automatically test the product according to the selected process. The equipment is easy to operate and has high testing efficiency. It is an ideal equipment for circuit breaker manufacturers to conduct batch rapid testing of circuit breakers. -

AC Charging Gun Comprehensive Tester

ZJ-CDQ01

Send Email Details

The instrument can detect the insulation and withstand voltage between AC three-phase charging guns (L1, L2, L3, N, E,) and AC single-phase charging guns (L, N, E,), the conduction between the gun tip and the end of the wire, and the resistance of the gun tip. All functions can be automatically tested at one time, which is efficient and labor-saving, and is suitable for full batch inspection in factories. -

EV Charger Aging Test Machine(With High Temperature Box)

HHLH-820C

Send Email Details

This AC charging gun aging tester adopts advanced computer control and energy-feeding load, and the test system is more intelligent, energy-saving and environmentally friendly.

1) Intelligence: The software automatically monitors aging, automatically cuts off the power supply and prompts alarm information when it fails or is defective

The equipment automatically short-circuits the faulty sample, and other stations continue to test

2) Energy saving: The energy-feeding load is used to achieve energy recovery to achieve energy saving

3) Environmental protection: The power is fed back to the power grid, which does not generate a lot of heat and avoids the increase of the ambient temperature of the test site

4) Traceability: The test data can be queried and traced in real time -

DC Charging Pile Test Device

EVD1000V-30KW*2

Send Email Details

The EVD1000V-30KW*2 DC charging pile test device consists of a load + national standard/European standard BMS simulation system, and uses a touch screen control method for simulated test operations (host computer remote control can also be used). It is mainly used for on-site installation, commissioning and function verification of DC charging pile products, and can also be used for online commissioning, offline testing, and function verification. The device truly simulates the charging process and various faults, avoiding the inconvenience of using a real electric vehicle as a test device, incomplete test content, inability to simulate real faults, inability to verify the auxiliary power system, time-consuming and labor-intensive charging and discharging of the vehicle's power battery, and shortened battery life due to frequent charging and discharging. At the same time, it can avoid damage to the test vehicle caused by charging pile failures.

- Home

-

Our Services

- Charging Gun Pile Testing Equipment

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Charging Gun Pile Testing Equipment

- Resistive Load Box

- Home Appliances And Medical Device Testing Instruments

- Connector Testing Equipment

- Inrush Current Detection Equipment

- AC Single-Phase And Three-Phase Charging Pile Testing Equipment

- Charging Gun Plug And Unplug Detection Equipment

- Vehicle Rolling Detection Equipment

- Charging Gun Seat Temperature Rise Detection Equipment

- Test Bench

- Testing Machine

- Test System

- Charging Pile Test Device

- Charging Pile Tester

- Detector

- Voltage Drop Tester

- Test Equipment

- Tester

- Load Bank

- Connector Harness Testing

- Display

- News

- About

- Contact Us

- Partners